Se você estiver interessado em cooperação, entre em contato conosco imediatamente e lhe daremos um feedback o mais breve possível!

![]() Whatsapp: +8613963585512

Whatsapp: +8613963585512

![]() E-mail : [email protected]

E-mail : [email protected]

| Item | Detalhes |

|---|---|

| Nome do produto | Bobina de aço inoxidável |

| Tipos de materiais | Aços inoxidáveis austeníticos (como 304, 304L, 316, 316L), aços inoxidáveis ferríticos (como 430), aços inoxidáveis martensíticos (como 410), aços inoxidáveis duplex (como 2205) |

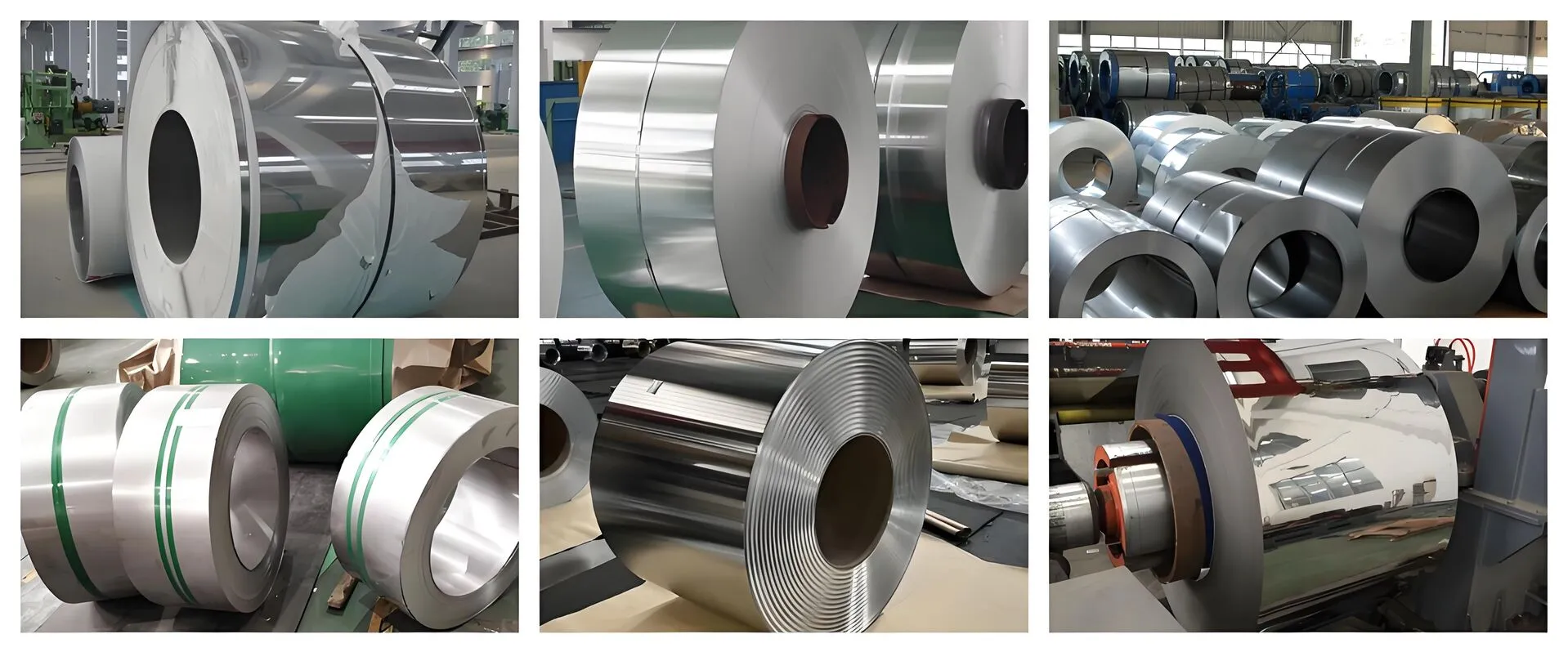

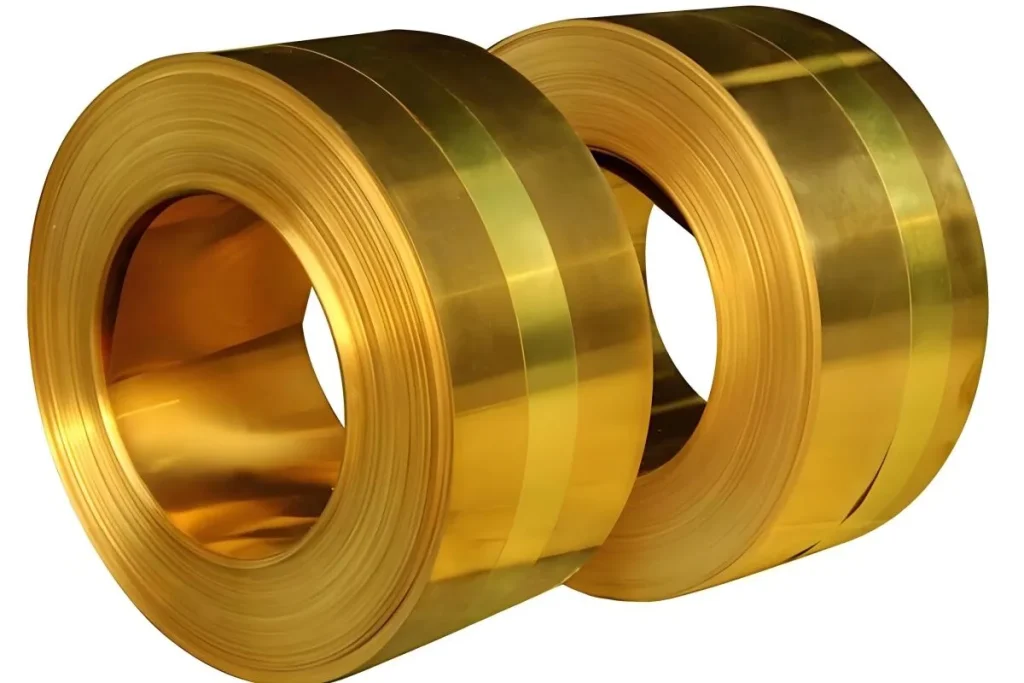

| Especificações | – Espessura: 0,1 mm – 12 mm – Largura: 600mm – 2000mm – Diâmetro interno: 508mm (convencional), 610mm – Diâmetro externo: determinado pelo peso e espessura da bobina, geralmente ≤ 2500 mm |

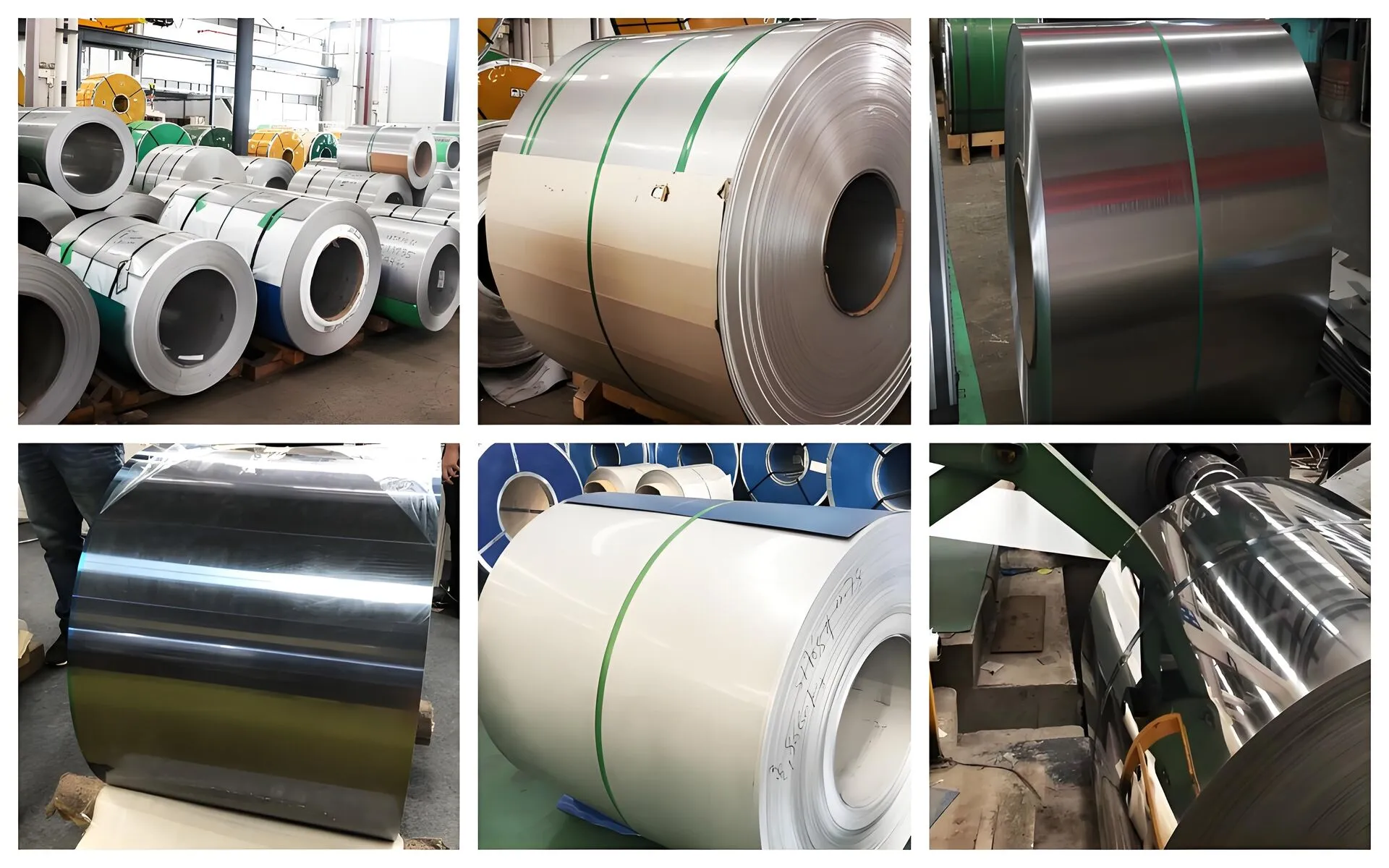

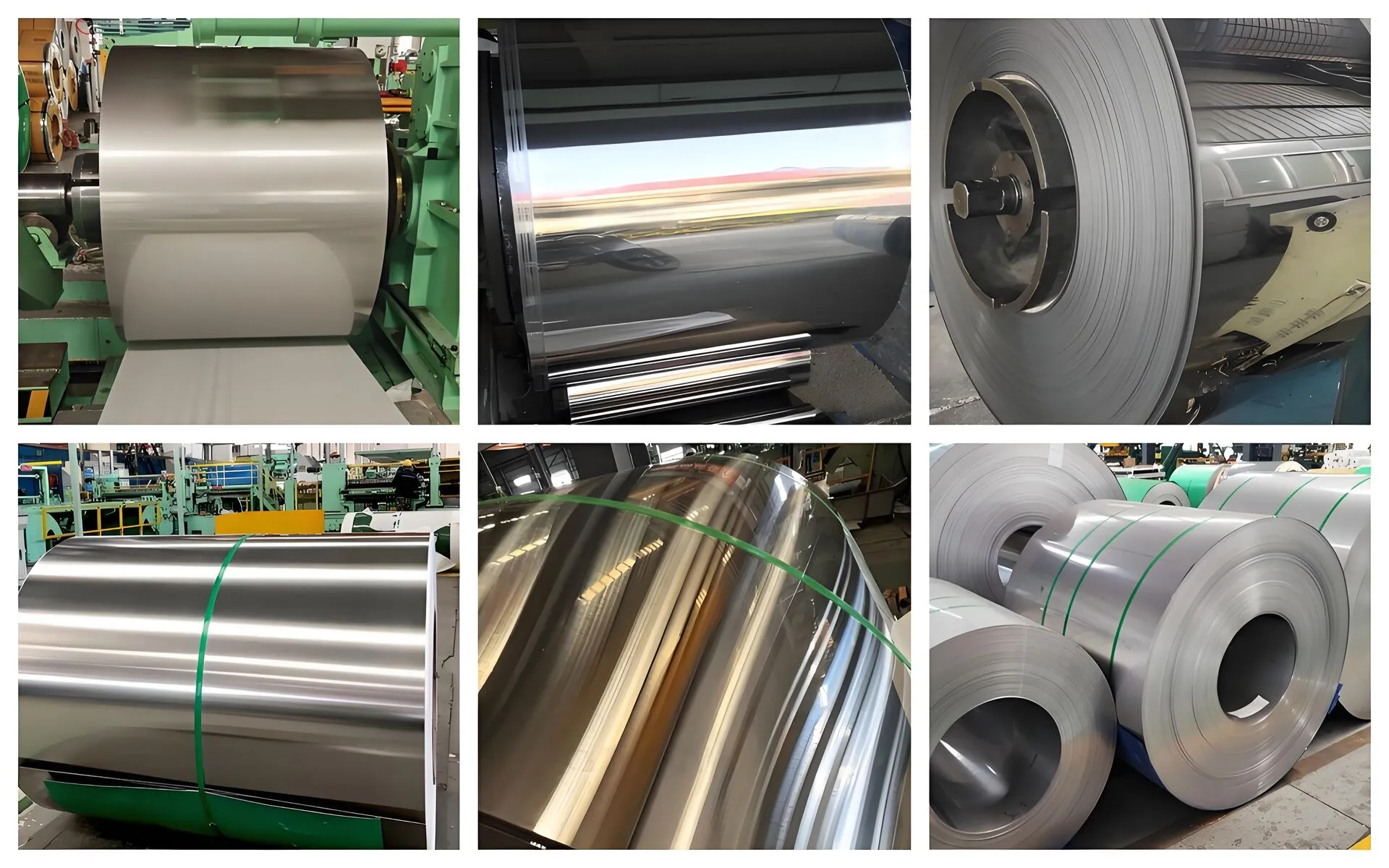

| Tratamentos de superfície | Superfície 2B (laminada a frio brilhante), superfície BA (recozida brilhante), No. 4 (acabamento acetinado), HL (acabamento fino), polimento espelhado; tratamento de passivação, revestimento de óleo para prevenção de ferrugem |

| Padrões | ASTM A240, ASTM A666, GB/T 3280, JIS G4305, DIN 17456, EN 10088-2 |

| Propriedades Mecânicas | – Resistência à tração: 520 – 1450 MPa (varia dependendo do tipo de aço) – Limite de escoamento: 205 – 1035 MPa – Alongamento: ≥ 35% (para alguns tipos de aço) |

| Resistência à corrosão | Teor de cromo ≥ 12%, formando uma densa película de óxido de Cr₂O₃ na superfície, resistente à corrosão atmosférica, à água e à corrosão ácido-base fraca; Os tipos de aço que contêm molibdênio (como 316L) têm excelente resistência à corrosão por íons cloreto |

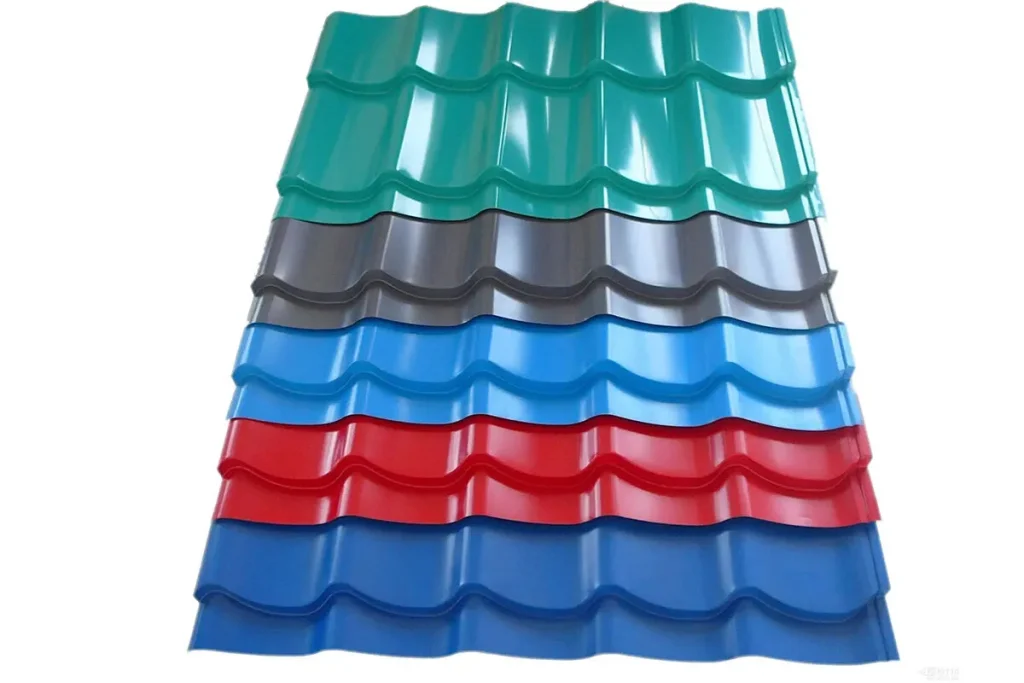

| Aplicações típicas | – Decoração arquitetônica: Painéis de parede cortina, tetos, painéis de elevador – Fabricação de eletrodomésticos: Painéis para refrigeradores, tambores internos para máquinas de lavar, carcaças para aparelhos de ar condicionado – Equipamentos alimentares: Tanques de armazenamento, correias transportadoras – Indústria química: Revestimentos de reatores, tubulações – Fabricação de automóveis: sistemas de escapamento, peças estruturais de carrocerias de veículos |

| Técnicas de Processamento | Laminação a frio (alta precisão, especificações finas), Laminação a quente (especificações espessas, baixo custo), Corte longitudinal (largura personalizada), Corte longitudinal (cortado em placas planas), Processamento de conformação (estampagem, dobra) |

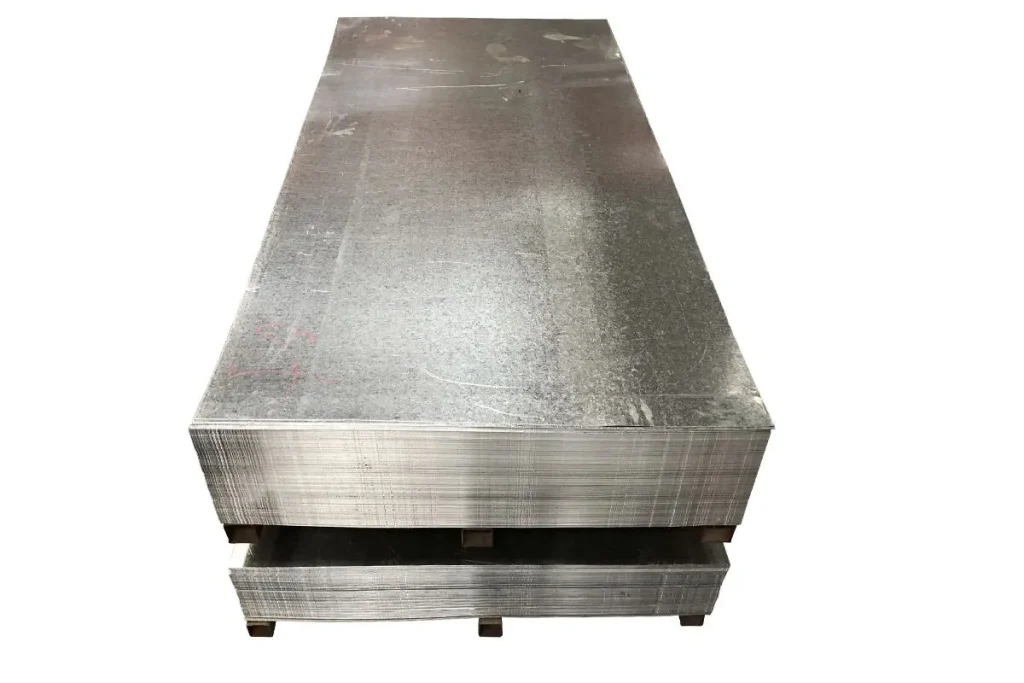

| Embalagem | Embrulhado com papel à prova de umidade + filme plástico e protegido por protetores de canto de aço nas bordas; Embalagem horizontal ou vertical, adequada para transporte marítimo e terrestre |

| Prazo de entrega | Especificações regulares: 5 a 10 dias úteis; Especificações personalizadas: 15 a 30 dias úteis |

| Certificações de Qualidade | Certificação do Sistema de Gestão da Qualidade ISO 9001, Relatório de Inspeção SGS, Certificação Ambiental RoHS |

Geralmente apresenta brilho metálico e superfície lisa. A aparência varia de acordo com os diferentes processos de tratamento de superfície, como superfície 2B, superfície BA, superfície fosca, superfície espelhada, etc.

Ela varia ligeiramente devido à composição específica do aço inoxidável, geralmente entre 7,93-8,03 g/cm3, por exemplo, a densidade do aço inoxidável 304 é de cerca de 7,93 g/cm3, e a densidade do aço inoxidável 316 é de cerca de 7,98 g/cm3.

Ponto de fusão: O ponto de fusão das bobinas de aço inoxidável é relativamente alto, geralmente em torno de 1398-1454°C, e os pontos de fusão de diferentes tipos de aço inoxidável variam.

Na faixa de temperatura ambiente até 100°C, o coeficiente de expansão linear médio é de cerca de 16,0-18,5×10⁻⁶/°C, e o coeficiente de expansão térmica aumentará ligeiramente com o aumento da temperatura.

A condutividade térmica é relativamente baixa, e sua condutividade térmica fica entre 16,3 e 21,5 W/(m·K), o que é apenas cerca de 1/3 do aço carbono.

Possui uma certa condutividade elétrica, mas não tão boa quanto a do cobre, alumínio e outros metais. Sua condutividade elétrica é de cerca de 20% a 30% de cobre.

Esta é uma das propriedades químicas mais importantes das bobinas de aço inoxidável. Por conter um alto teor de cromo (Cr), é fácil formar uma película densa de óxido de cromo na superfície, em contato com o ar. Essa película de óxido impede que o metal interno entre em contato com o ar, a água e outros meios corrosivos, proporcionando assim uma boa resistência à corrosão. Quando o teor de cromo atinge mais de 12%, a resistência à corrosão do aço inoxidável aumenta significativamente. Algumas bobinas especiais de aço inoxidável, como o aço inoxidável 316, apresentam melhor resistência à corrosão por íons cloreto devido à adição de elementos de molibdênio (Mo), sendo adequadas para alguns ambientes corrosivos mais severos, como ambientes marinhos.

À temperatura ambiente, as bobinas de aço inoxidável apresentam boa resistência à oxidação. Em ambientes de alta temperatura, a película de óxido na superfície do aço inoxidável também pode desempenhar um certo papel protetor, impedindo que o metal seja ainda mais oxidado. No entanto, com o aumento da temperatura, o desempenho antioxidante muda, e diferentes tipos de aço inoxidável têm diferentes capacidades antioxidantes em altas temperaturas. Por exemplo, a incrustação de óxido do aço inoxidável 304 abaixo de 870 °C oferece boa proteção, mas em temperaturas mais altas, a taxa de oxidação acelera.

As bobinas de aço inoxidável apresentam boa estabilidade em meios químicos gerais e não reagem quimicamente com ácidos, álcalis, sais, etc. No entanto, sob algumas condições específicas, como ambientes com altas concentrações de ácidos fortes e álcalis fortes, ou na presença de catalisadores específicos, o aço inoxidável também pode sofrer corrosão ou outras reações químicas. Por exemplo, em ácido sulfúrico concentrado, o aço inoxidável pode ser passivado, mas se a concentração e a temperatura do ácido sulfúrico excederem uma determinada faixa, ele também corroerá o aço inoxidável.

Algumas bobinas de aço inoxidável são magnéticas, como o aço inoxidável ferrítico e o aço inoxidável martensítico, enquanto o aço inoxidável austenítico geralmente é não magnético ou fracamente magnético. No entanto, durante o processamento a frio, o aço inoxidável austenítico pode produzir um certo grau de magnetismo.

Ultra – alta resistência e tenacidade para resistir a cargas e impactos extremos

Ultra – alta resistência e tenacidade para resistir a cargas e impactos extremos

Com tratamento anticorrosivo, é resistente às intempéries e à corrosão, podendo durar muito tempo.

100% reciclável, reutilizável, de baixo carbono e redutor de consumo

O processamento é rápido e preciso, e o projeto é entregue rapidamente.

Passe por certificações internacionais como ISO e ASTM, com qualidade confiável.

Crie especificações e formas exclusivas conforme necessário

Equipe de serviço global, fornecendo suporte técnico completo pós-venda

Nossa fábrica produz uma gama completa de produtos de aço, incluindo, entre outros, vigas estruturais, barras de aço, chapas e bobinas. Também oferecemos soluções personalizadas, atendendo a dimensões e composições específicas, de acordo com as necessidades do cliente.

Todos os nossos produtos de aço atendem a padrões internacionais e passam por rigorosos testes de garantia de qualidade. Possuímos diversas certificações, incluindo a ISO 9001, que reforçam nosso compromisso com a qualidade. Cada lote de produto vem com uma certificação detalhando sua classificação e padrões de conformidade.

Sim, estamos preparados para gerenciar volumes significativos de pedidos, mesmo dentro de prazos apertados, graças aos nossos processos operacionais avançados, força de trabalho considerável e rede logística eficiente. No entanto, sugerimos sempre entrar em contato conosco com informações específicas o mais cedo possível para obter os melhores resultados.

A sustentabilidade está no centro das nossas operações. Utilizamos tecnologias de eficiência energética, reciclamos resíduos e seguimos rigorosos protocolos ambientais para minimizar nossa pegada ecológica. Nosso compromisso vai além da conformidade, buscando uma abordagem sustentável e voltada para o futuro em tudo o que fazemos.

A segurança dos trabalhadores é primordial. Nossa fábrica cumpre todas as normas de saúde e segurança, oferecendo treinamentos regulares, aplicando protocolos rigorosos no local e equipando nossa equipe com equipamentos de segurança avançados. Acreditamos que um trabalhador seguro é um trabalhador capacitado.

Com certeza. Nos orgulhamos da nossa capacidade de fornecer soluções personalizadas. Nossa equipe de especialistas colabora estreitamente com os clientes para entender suas necessidades, oferecendo composições, cortes e acabamentos personalizados, exclusivos para as demandas de seus projetos.

Gerenciamos a logística por meio de parceiros de confiança, garantindo entregas pontuais e seguras. Os clientes recebem informações de rastreamento assim que os pedidos são despachados e podem monitorar a remessa em tempo real. Além disso, nossa equipe de atendimento ao cliente está sempre à disposição para ajudar.

Garantimos a qualidade dos nossos produtos. Em casos raros de defeitos ou não conformidade, temos uma política de devolução ou troca transparente. Recomendamos que os clientes entrem em contato conosco dentro de um prazo especificado após o recebimento, e prometemos uma resolução rápida e justa, de acordo com nossos termos e condições.