Si está interesado en cooperar, contáctenos de inmediato, ¡le daremos su opinión lo antes posible!

![]() WhatsApp: +8613963585512

WhatsApp: +8613963585512

![]() Correo electrónico : [email protected]

Correo electrónico : [email protected]

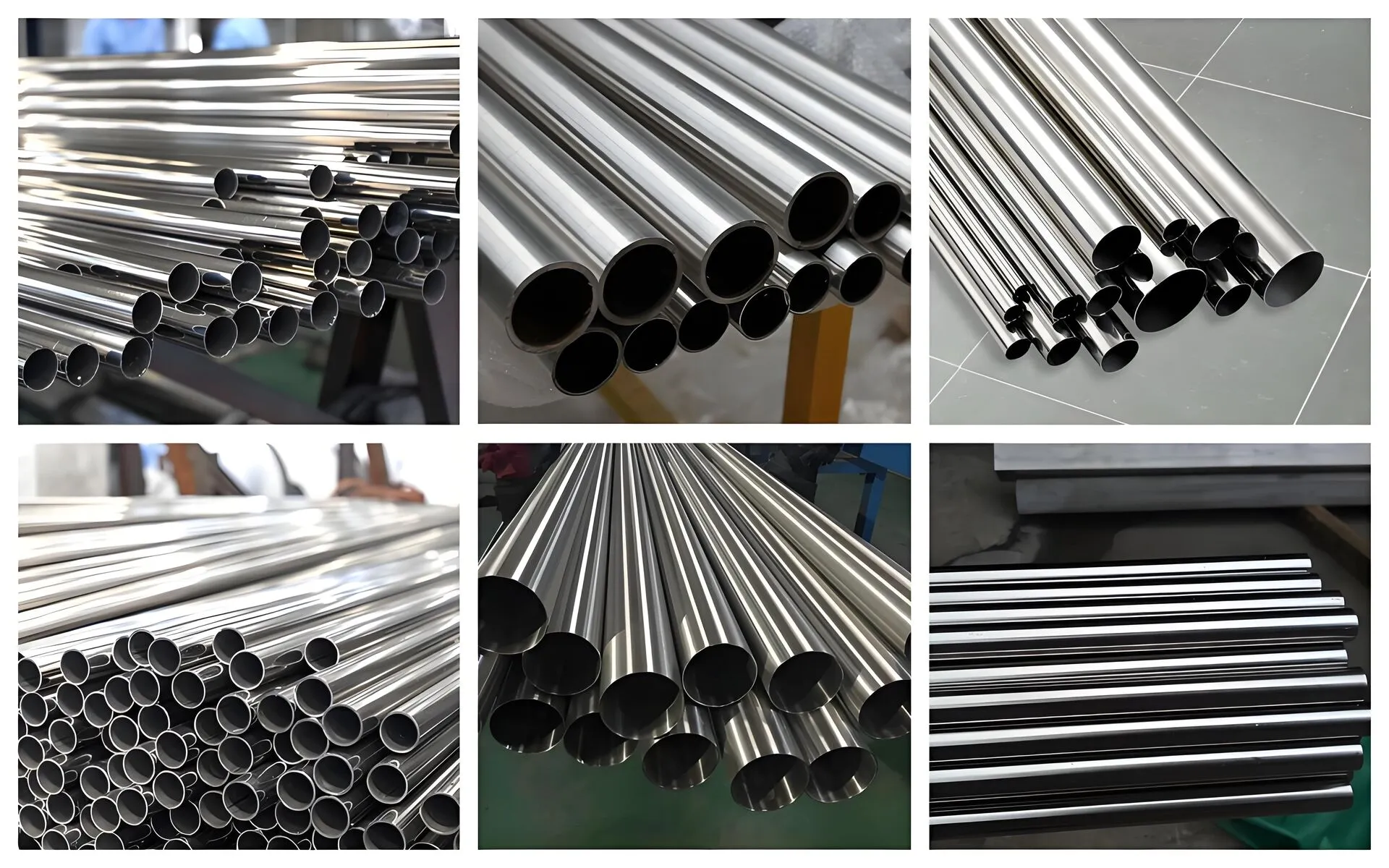

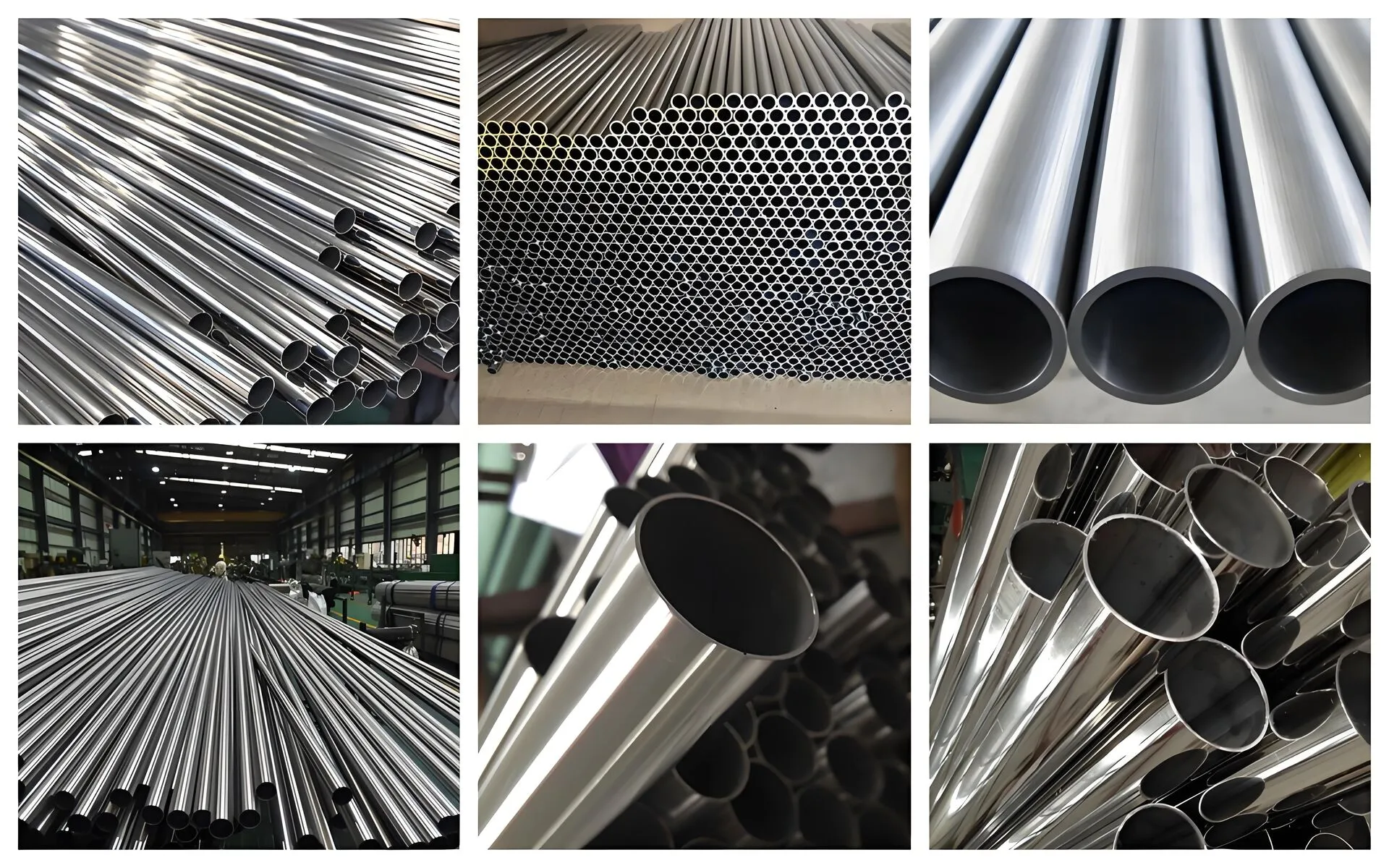

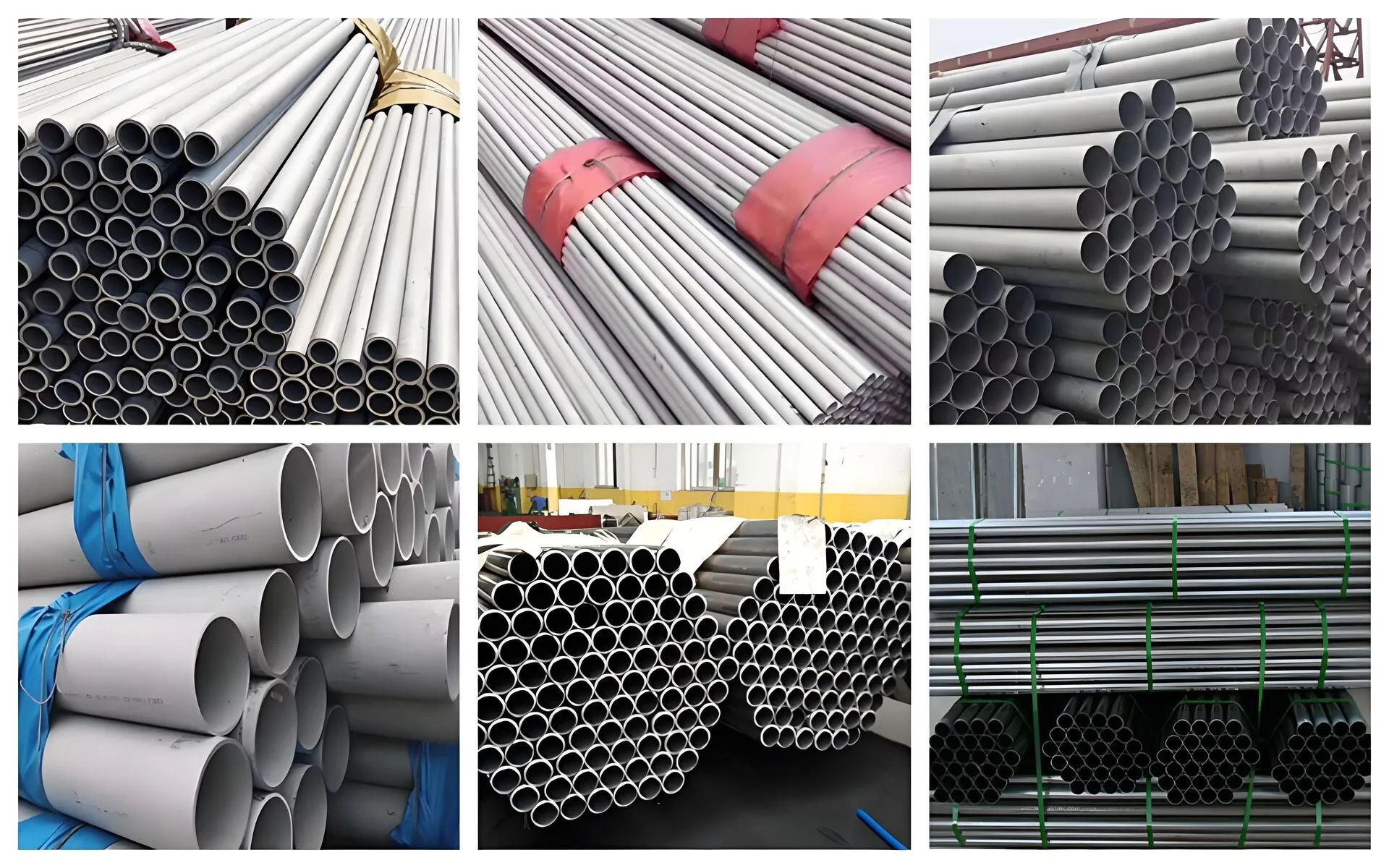

| Nombre del producto | Tubo de acero inoxidable |

|---|---|

| Tipo de material | Acero inoxidable (tubos cuadrados, tubos rectangulares, tubos redondos) |

| #efefef | Tubos cuadrados, tubos rectangulares, tubos redondos |

| Espesor | 0,5-75 mm (general); 0,16 mm-4,0 mm (para tubos cuadrados/rectangulares/redondos de especificaciones específicas) |

| Presupuesto | – Tubos redondos: Diámetro exterior 8mm-680mm – Tubos cuadrados: 10x10mm-300x300mm – Tubos rectangulares: 10x20mm-120x180mm |

| Tratamiento de superficies | Pulido, recocido, decapado, acabado brillante. |

| Proceso de producción | Laminación en frío / Laminación en caliente |

| Grados de acero | 201, 202, 304, 304L, 304N, 309S, 310S, 316, 316L, 316N, 316Ti, 317, 317L, 321, 347, 347H |

| Estándares de ejecución | ASTM A213, A312, A269, A778, A789; DIN 17456, 17457, 17459; JIS G3459, G3463; GOST 9941; EN 10216; BS 3605; ES 13296 |

| Tolerancia | – Diámetro exterior: ±0,5 mm – Espesor: ±0,05 mm – Longitud: ±5 mm |

| Elementos de prueba | Prueba de aplanamiento, prueba de expansión, prueba de presión hidrostática, prueba de corrosión intergranular, prueba de tratamiento térmico |

| Embalaje | Embalaje de exportación estándar |

| Métodos de pago | Transferencia telegráfica (T/T), carta de crédito (L/C), Western Union |

| El tiempo de entrega | 10 días hábiles a partir de la recepción del depósito |

| Áreas de aplicación | Decoración, construcción, tapicería, sistemas de suministro de agua, pasamanos, barandillas, escaleras, puertas, ventanas, balcones, cercas, bancos, muebles, etc. |

| Servicios de procesamiento | Procesamiento personalizado, corte longitudinal (Kaiping), corte, procesamiento de patrones. |

La densidad de las tuberías de acero inoxidable varía ligeramente según el tipo de acero, generalmente entre 7,75 y 8,05 g/cm³. Por ejemplo, la densidad del acero inoxidable 304 es de aproximadamente 7,93 g/cm³, y la del acero inoxidable 316, de aproximadamente 7,98 g/cm³.

Generalmente, se encuentra entre 1398 y 1454 °C, y las diferentes composiciones de aleación dan lugar a diferentes puntos de fusión. Por ejemplo, el punto de fusión del acero inoxidable 304 es de aproximadamente 1400 a 1450 °C, mientras que el del acero inoxidable 310S tiene un punto de fusión relativamente más alto, de aproximadamente 1470 a 1530 °C, debido a su alto contenido de cromo y níquel.

Coeficiente de expansión térmica: Con los cambios de temperatura, las tuberías de acero inoxidable se expanden y contraen. En general, su coeficiente de expansión térmica se encuentra entre (10-20) × 10⁻⁶/℃. Por ejemplo, el coeficiente de expansión térmica del acero inoxidable 304 a 20-100 ℃ es de aproximadamente 17,3 × 10⁻⁶/℃.

El acero inoxidable tiene una conductividad térmica baja, generalmente entre 10 y 30 W/(m·K). Por ejemplo, el acero inoxidable 304 tiene una conductividad térmica de aproximadamente 16,2 W/(m·K), mucho menor que la de metales como el cobre (aproximadamente 386 W/(m·K)) y el aluminio (aproximadamente 203 W/(m·K)).

La conductividad eléctrica de las tuberías de acero inoxidable es relativamente baja, y suele estar entre (1,3 y 1,6) × 10⁶ S/m. La conductividad eléctrica del acero inoxidable 304 es de aproximadamente 1,4 × 10⁶ S/m, inferior a la de los metales puros.

Esta es una de las propiedades químicas más importantes de las tuberías de acero inoxidable. El acero inoxidable contiene elementos de aleación como el cromo y el níquel, que reaccionan con el oxígeno del aire para formar una densa película de óxido en la superficie (el componente principal es Cr₂O₃). Esta película de óxido impide que el metal interno reaccione químicamente con sustancias externas, lo que le confiere una buena resistencia a la corrosión. Por ejemplo, el acero inoxidable 304 presenta buena resistencia a la corrosión en la atmósfera, el agua y algunas soluciones ácidas y alcalinas débiles; el acero inoxidable 316 presenta una mejor resistencia a la corrosión por iones cloruro gracias a la adición de molibdeno, y se utiliza a menudo en entornos marinos o en contacto con medios con iones cloruro.

A altas temperaturas, las tuberías de acero inoxidable mantienen buenas propiedades antioxidantes. La presencia de cromo permite que el acero inoxidable forme una película de óxido estable a altas temperaturas, lo que previene una mayor oxidación. Aceros inoxidables como el 309S y el 310S tienen un alto contenido de cromo y níquel, se pueden utilizar durante mucho tiempo en entornos de alta temperatura, poseen buenas propiedades antioxidantes y son aptos para tubos de hornos de alta temperatura, elementos calefactores, etc.

Las tuberías de acero inoxidable son relativamente estables en entornos químicos generales y no reaccionan violentamente con facilidad con sustancias químicas comunes. Sin embargo, en ciertas condiciones, como ácidos oxidantes fuertes (como el ácido nítrico y el ácido sulfúrico concentrados), altas temperaturas y soluciones alcalinas de alta concentración, el acero inoxidable también puede corroerse o reaccionar químicamente. No obstante, ajustando la composición y el proceso de tratamiento superficial del acero inoxidable, se puede mejorar su estabilidad en entornos químicos específicos.

Las tuberías de acero inoxidable se utilizan ampliamente en diversos campos gracias a su excelente resistencia a la corrosión, robustez y estética. En la decoración arquitectónica, se emplean a menudo en pasamanos, barandillas, marcos de puertas y ventanas, y en la decoración de muros cortina. No solo son duraderas, sino que también pueden mejorar la apariencia del edificio. Las industrias alimentaria y farmacéutica aprovechan sus características higiénicas, no tóxicas y de fácil limpieza para fabricar equipos de procesamiento de alimentos, tuberías farmacéuticas y contenedores de almacenamiento, garantizando así un proceso de producción seguro y libre de contaminación. En cuanto a suministros de cocina y baño, las tuberías y grifos de agua de acero inoxidable son la primera opción para las instalaciones de agua domésticas gracias a su resistencia a la corrosión y larga vida útil. En el sector industrial, se utilizan tipos especiales de tuberías de acero inoxidable, como el 316, en tuberías químicas y equipos de extracción de petróleo, que soportan ácidos y álcalis fuertes, así como entornos de alta temperatura y alta presión. En el transporte, las tuberías de acero inoxidable se utilizan para fabricar sistemas de escape de automóviles y estructuras de vagones de metro, logrando un equilibrio entre ligereza y alta resistencia.

Ultraalta resistencia y tenacidad para soportar cargas e impactos extremos.

Ultraalta resistencia y tenacidad para soportar cargas e impactos extremos.

Con tratamiento anticorrosión, es resistente a la intemperie y a la corrosión, y puede servir durante mucho tiempo.

100% reciclable, reutilizable, bajo en carbono y que reduce el consumo

El procesamiento es rápido y preciso y el proyecto se entrega rápidamente.

Pasar certificaciones internacionales como ISO y ASTM, con calidad confiable.

Cree especificaciones y formas exclusivas según sea necesario

Equipo de servicio global que brinda soporte técnico posventa completo.

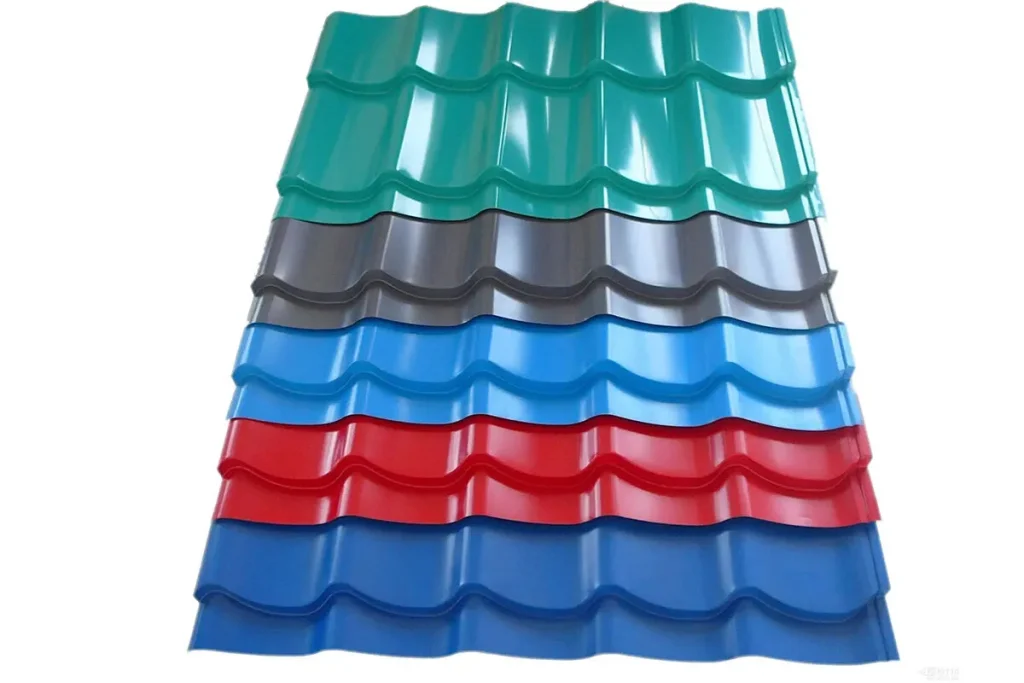

Nuestra fábrica fabrica una amplia gama de productos de acero, incluyendo, entre otros, vigas estructurales, barras de acero, placas y bobinas. También ofrecemos soluciones a medida que se adaptan a las dimensiones y composiciones específicas de cada cliente.

Por supuesto, todos nuestros productos de acero cumplen con los estándares internacionales y se someten a rigurosas pruebas de calidad. Contamos con diversas certificaciones, incluida la ISO 9001, que demuestran nuestro compromiso con la calidad. Cada lote de producto incluye una certificación que detalla su grado y los estándares de cumplimiento.

Sí, estamos preparados para gestionar grandes volúmenes de pedidos incluso con plazos ajustados gracias a nuestros avanzados procesos operativos, nuestra amplia plantilla y nuestra eficiente red logística. Sin embargo, le recomendamos que nos contacte con los detalles lo antes posible para obtener los mejores resultados.

La sostenibilidad es fundamental en nuestras operaciones. Utilizamos tecnologías de eficiencia energética, reciclamos materiales de desecho y seguimos estrictos protocolos ambientales para minimizar nuestra huella ecológica. Nuestro compromiso va más allá del cumplimiento normativo, buscando un enfoque sostenible y con visión de futuro en todo lo que hacemos.

La seguridad de los trabajadores es primordial. Nuestra fábrica cumple con todas las normas de salud y seguridad, impartiendo capacitación periódica, aplicando estrictos protocolos en planta y equipando a nuestro personal con equipo de seguridad avanzado. Creemos que un trabajador seguro es un trabajador empoderado.

Por supuesto. Nos enorgullecemos de nuestra capacidad para ofrecer soluciones a medida. Nuestro equipo de expertos colabora estrechamente con nuestros clientes para comprender sus necesidades, ofreciendo composiciones, cortes y acabados personalizados que se adaptan a las necesidades de su proyecto.

Gestionamos la logística a través de socios de confianza, garantizando entregas puntuales y seguras. Los clientes reciben información de seguimiento una vez enviados sus pedidos y pueden monitorear su envío en tiempo real. Además, nuestro equipo de atención al cliente está siempre disponible para ayudarle.

Respaldamos la calidad de nuestros productos. En el raro caso de defectos o incumplimientos, contamos con una política de devolución o cambio transparente. Animamos a los clientes a contactarnos dentro de un plazo específico tras la recepción, y prometemos una resolución rápida y justa, de acuerdo con nuestros términos y condiciones.