إذا كنت مهتمًا بالتعاون، فيرجى الاتصال بنا على الفور، وسنقدم لك ردود الفعل في أقرب وقت ممكن!

![]() واتساب : +8613963585512

واتساب : +8613963585512

![]() بريد إلكتروني : راشيل@sdxhjmetal.com

بريد إلكتروني : راشيل@sdxhjmetal.com

| غرض | تفاصيل |

|---|---|

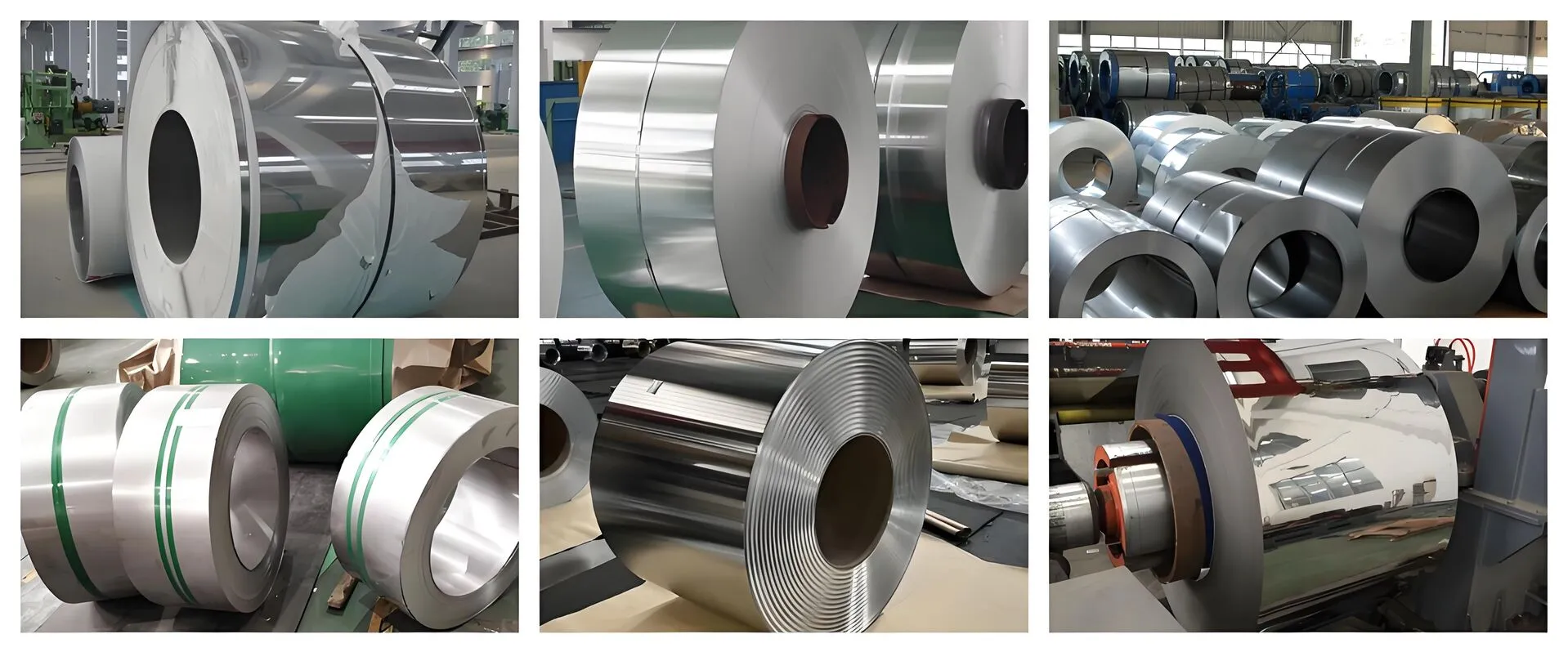

| اسم المنتج | لفائف الفولاذ المقاوم للصدأ |

| أنواع المواد | الفولاذ المقاوم للصدأ الأوستنيتي (مثل 304، 304L، 316، 316L)، الفولاذ المقاوم للصدأ الفريتي (مثل 430)، الفولاذ المقاوم للصدأ المارتنسيتي (مثل 410)، الفولاذ المقاوم للصدأ المزدوج (مثل 2205) |

| تحديد | – السُمك: 0.1 مم – 12 مم – العرض: 600 مم – 2000 مم - القطر الداخلي: 508 مم (تقليدي)، 610 مم - القطر الخارجي: يتم تحديده من خلال وزن الملف وسمكه، وعادة ما يكون ≤ 2500 مم |

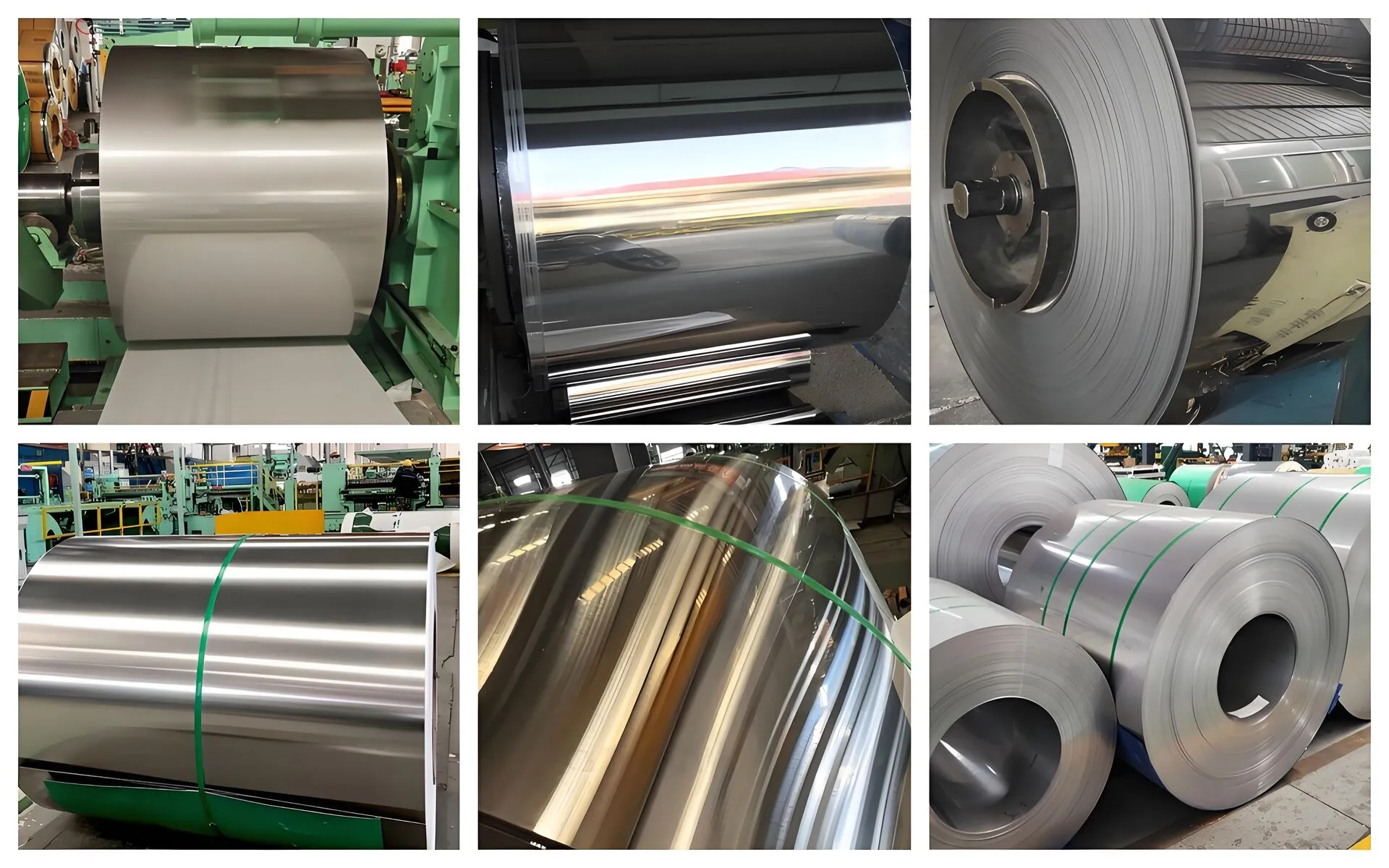

| معالجات السطح | سطح 2B (مدرفل على البارد لامع)، سطح BA (مُلَدَّن لامع)، رقم 4 (لمسة نهائية ساتان)، HL (لمسة نهائية شعرية)، تلميع المرآة؛ معالجة التخميل، طلاء زيتي لمنع الصدأ |

| المعايير | ASTM A240، ASTM A666، GB/T 3280، JIS G4305، DIN 17456، EN 10088-2 |

| الخصائص الميكانيكية | – قوة الشد: 520 – 1450 ميجا باسكال (تختلف حسب درجة الفولاذ) – قوة الخضوع: 205 – 1035 ميجا باسكال – الاستطالة: ≥ 35% (لبعض درجات الفولاذ) |

| مقاومة التآكل | محتوى الكروم ≥ 12%، يشكل طبقة كثيفة من أكسيد Cr₂O₃ على السطح، مقاوم للتآكل الجوي والماء والتآكل الحمضي القاعدي الضعيف؛ تتمتع درجات الفولاذ التي تحتوي على الموليبدينوم (مثل 316L) بمقاومة ممتازة لتآكل أيونات الكلوريد |

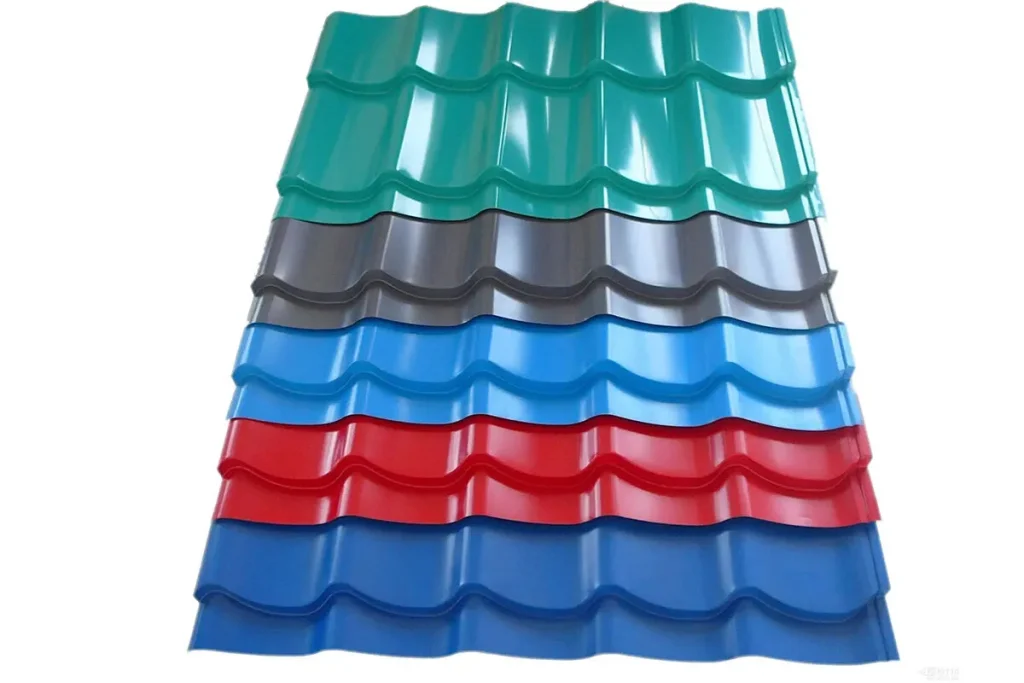

| التطبيقات النموذجية | - الديكور المعماري: ألواح الجدران الستارية، والأسقف، وألواح المصاعد - تصنيع الأجهزة المنزلية: لوحات الثلاجات، والبراميل الداخلية للغسالات، وأغطية مكيفات الهواء - معدات الأغذية: خزانات التخزين، والأحزمة الناقلة - الصناعة الكيميائية: بطانات المفاعلات والأنابيب - تصنيع السيارات: أنظمة العادم، وأجزاء هيكل السيارة |

| تقنيات المعالجة | الدرفلة الباردة (دقة عالية، مواصفات رقيقة)، الدرفلة الساخنة (مواصفات سميكة، تكلفة منخفضة)، التقطيع (عرض مخصص)، القطع حسب الطول (قطع إلى صفائح مسطحة)، معالجة التشكيل (الختم، الانحناء) |

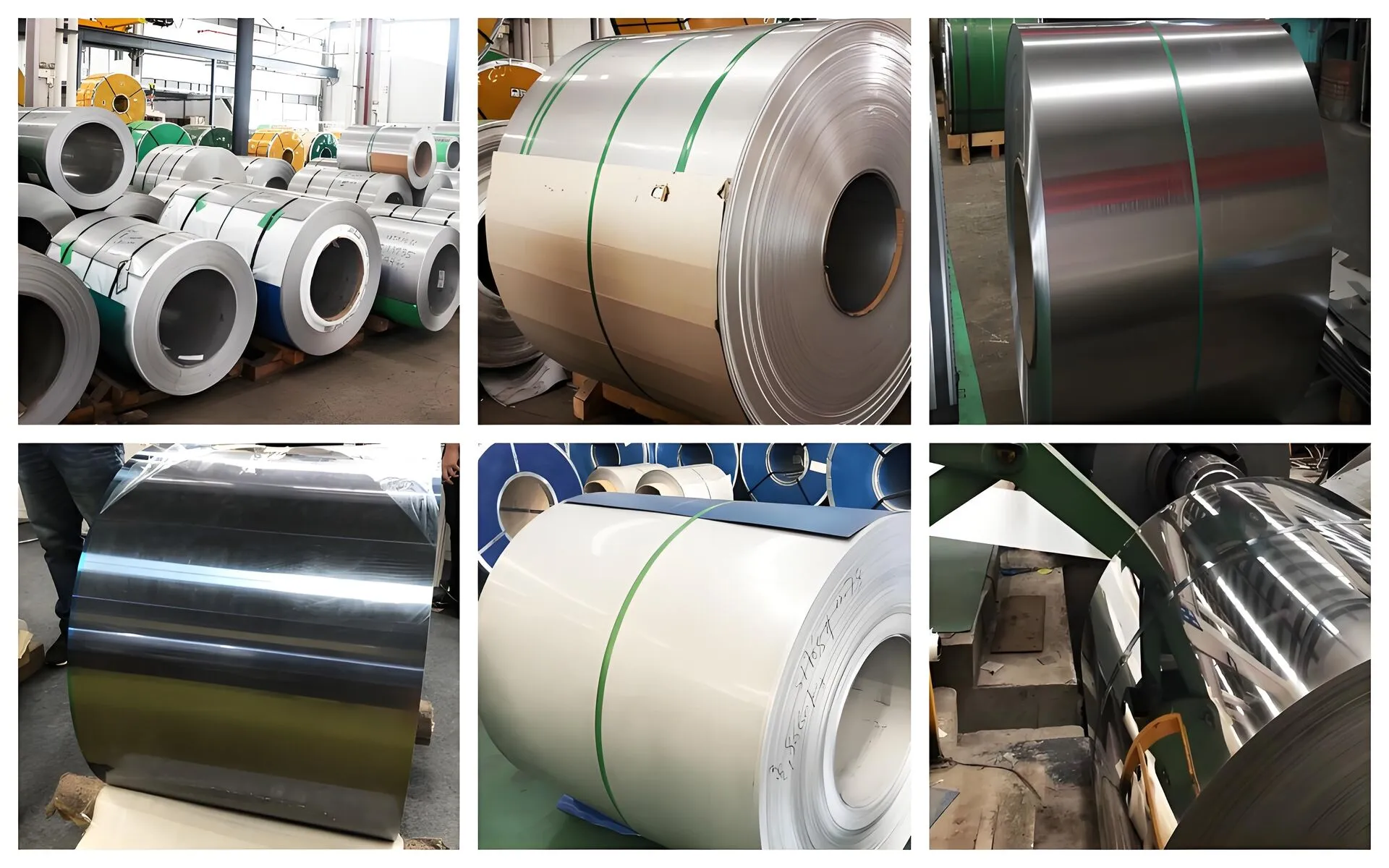

| التعبئة والتغليف | مغلفة بورق مقاوم للرطوبة + فيلم بلاستيكي، ومحمية بحماة زوايا فولاذية على الحواف؛ تغليف أفقي أو رأسي، مناسب للنقل البحري والبري |

| موعد التسليم | المواصفات العادية: 5 – 10 أيام عمل؛ المواصفات المخصصة: 15 – 30 يوم عمل |

| شهادات الجودة | شهادة نظام إدارة الجودة ISO 9001، تقرير تفتيش SGS، شهادة RoHS البيئية |

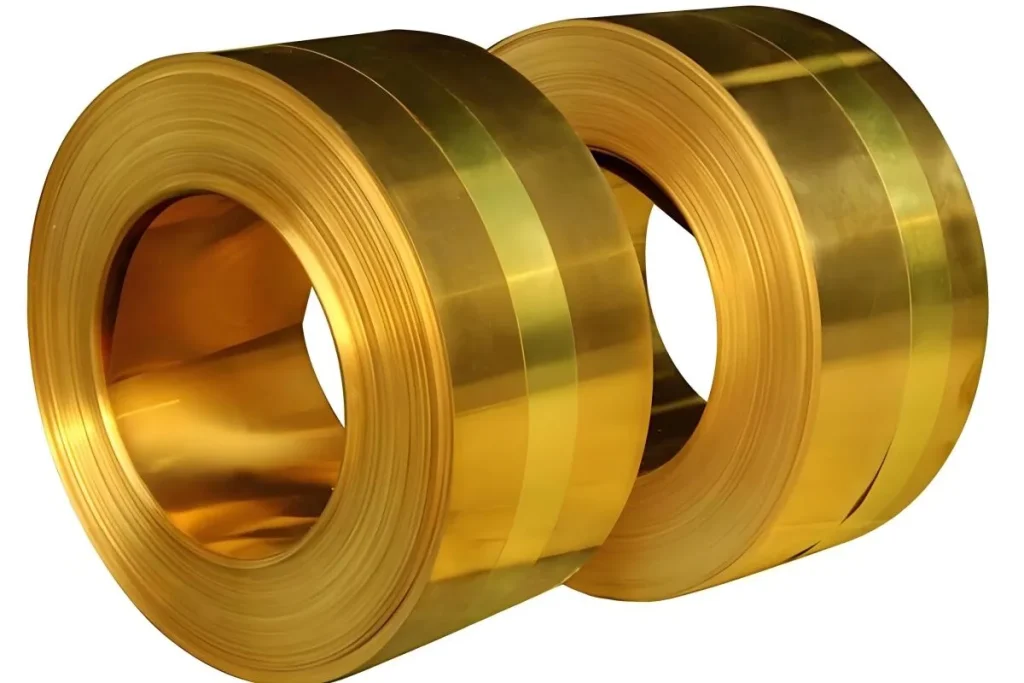

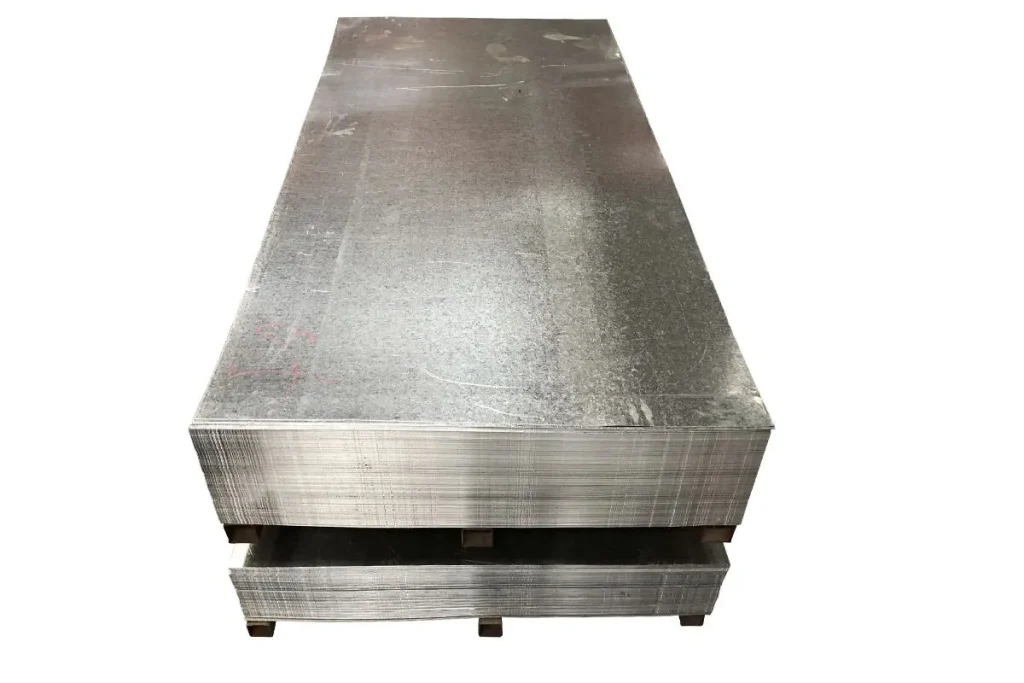

عادةً ما يكون له بريق معدني وسطح أملس. يختلف المظهر باختلاف عمليات معالجة السطح، مثل سطح 2B، وسطح BA، والسطح المُجمد، وسطح المرآة، إلخ.

يختلف قليلاً بسبب التركيب المحدد للفولاذ المقاوم للصدأ، وعادة ما يكون بين 7.93-8.03 جم / سم 3، على سبيل المثال، تبلغ كثافة الفولاذ المقاوم للصدأ 304 حوالي 7.93 جم / سم 3، وتبلغ كثافة الفولاذ المقاوم للصدأ 316 حوالي 7.98 جم / سم 3.

نقطة الانصهار: نقطة انصهار ملفات الفولاذ المقاوم للصدأ مرتفعة نسبيًا، وعادةً ما تكون حوالي 1398-1454 درجة مئوية، وستختلف نقاط انصهار أنواع مختلفة من الفولاذ المقاوم للصدأ.

في نطاق درجة حرارة الغرفة إلى 100 درجة مئوية، يبلغ متوسط معامل التمدد الخطي حوالي 16.0-18.5 × 10⁻⁶/℃، وسيزداد معامل التمدد الحراري قليلاً مع زيادة درجة الحرارة.

تعتبر الموصلية الحرارية ضعيفة نسبيًا، وتتراوح بين 16.3 و21.5 واط/(م·ك)، وهو ما يعادل 1/3 فقط من الفولاذ الكربوني.

يتمتع بموصلية كهربائية جيدة، لكنها ليست بجودة النحاس والألومنيوم والمعادن الأخرى. موصليته الكهربائية تتراوح بين ٢٠١TP3T و٣٠١TP3T من النحاس.

هذه إحدى أهم الخصائص الكيميائية لملفات الفولاذ المقاوم للصدأ. لاحتوائها على نسبة عالية من عنصر الكروم (Cr)، يسهل تكوين طبقة كثيفة من أكسيد الكروم على سطحها في الهواء. تمنع هذه الطبقة المعدنية الداخلية من التلامس مع الهواء والماء والمواد المسببة للتآكل، مما يمنحها مقاومة جيدة للتآكل. عندما يتجاوز محتوى الكروم 12%، تتحسن مقاومة الفولاذ المقاوم للصدأ للتآكل بشكل ملحوظ. بعض ملفات الفولاذ المقاوم للصدأ الخاصة، مثل الفولاذ المقاوم للصدأ 316، تتمتع بمقاومة أفضل لتآكل أيونات الكلوريد بفضل إضافة عناصر الموليبدينوم (Mo)، وهي مناسبة للبيئات التآكلية الشديدة، مثل البيئات البحرية.

في درجة حرارة الغرفة، تتمتع لفائف الفولاذ المقاوم للصدأ بمقاومة جيدة للأكسدة. وفي البيئات ذات درجات الحرارة المرتفعة، تلعب طبقة الأكسيد على سطح الفولاذ المقاوم للصدأ دورًا وقائيًا، مما يمنع تأكسد المعدن. ومع ذلك، مع ارتفاع درجة الحرارة، يتغير أداء مقاومة الأكسدة، وتختلف أنواع الفولاذ المقاوم للصدأ المختلفة في قدرتها على مقاومة الأكسدة عند درجات الحرارة العالية. على سبيل المثال، يتمتع مقياس أكسيد الفولاذ المقاوم للصدأ 304 بحماية جيدة عند درجات حرارة أقل من 870 درجة مئوية، ولكن عند درجات الحرارة الأعلى، يتسارع معدل الأكسدة.

تتميز ملفات الفولاذ المقاوم للصدأ بثبات جيد في الأوساط الكيميائية العامة، ولا تتفاعل بسهولة مع الأحماض والقلويات والأملاح وغيرها. ومع ذلك، في ظل ظروف خاصة، مثل بيئات الأحماض والقلويات القوية عالية التركيز، أو في وجود محفزات محددة، قد يتآكل الفولاذ المقاوم للصدأ أو يتعرض لتفاعلات كيميائية أخرى. على سبيل المثال، في حمض الكبريتيك المركز، يمكن تخميل الفولاذ المقاوم للصدأ، ولكن إذا تجاوز تركيز حمض الكبريتيك ودرجة حرارته نطاقًا معينًا، فسيؤدي ذلك إلى تآكل الفولاذ المقاوم للصدأ أيضًا.

بعض ملفات الفولاذ المقاوم للصدأ مغناطيسية، مثل الفولاذ المقاوم للصدأ الفريتي والفولاذ المقاوم للصدأ المارتنسيتي، بينما يكون الفولاذ المقاوم للصدأ الأوستنيتي عادةً غير مغناطيسي أو ضعيف المغناطيسية. مع ذلك، أثناء المعالجة الباردة، قد يُنتج الفولاذ المقاوم للصدأ الأوستنيتي درجة معينة من المغناطيسية.

فائقة القوة والمتانة لمقاومة الأحمال والصدمات الشديدة

فائقة القوة والمتانة لمقاومة الأحمال والصدمات الشديدة

مع المعالجة المضادة للتآكل، فهي مقاومة للطقس ومقاومة للتآكل، ويمكن أن تخدم لفترة طويلة.

100% قابلة لإعادة التدوير والاستخدام ومنخفضة الكربون ومقللة للاستهلاك

تتم المعالجة بسرعة ودقة، ويتم تسليم المشروع بسرعة.

الحصول على شهادات دولية مثل ISO وASTM، مع جودة موثوقة.

إنشاء مواصفات وأشكال حصرية حسب الحاجة

فريق خدمة عالمي يقدم الدعم الفني الكامل بعد البيع

يُصنّع مصنعنا مجموعةً شاملةً من منتجات الفولاذ، تشمل على سبيل المثال لا الحصر، العوارض الإنشائية، والقضبان، والصفائح، واللفائف الفولاذية. كما نُقدّم حلولاً مُصمّمة خصيصاً لتناسب أبعاداً وتركيبات مُحدّدة وفقاً لمتطلبات عملائنا.

بالتأكيد، جميع منتجاتنا الفولاذية تلتزم بالمعايير الدولية وتخضع لاختبارات ضمان جودة صارمة. نحمل شهادات متنوعة، منها شهادة ISO 9001، مما يؤكد التزامنا بالجودة. تأتي كل دفعة من المنتجات مع شهادة توضح درجتها ومعايير امتثالها.

نعم، نحن قادرون على إدارة كميات كبيرة من الطلبات حتى في ظل الجداول الزمنية المحدودة، بفضل عملياتنا التشغيلية المتطورة، وكوادرنا البشرية الكبيرة، وشبكتنا اللوجستية الفعّالة. ومع ذلك، ننصح دائمًا بالتواصل معنا للحصول على التفاصيل في أقرب وقت ممكن لتحقيق أفضل النتائج.

الاستدامة هي جوهر عملياتنا. نستخدم تقنيات موفرة للطاقة، ونعيد تدوير النفايات، ونلتزم ببروتوكولات بيئية صارمة لتقليل بصمتنا البيئية. يتجاوز التزامنا مجرد الامتثال، إذ نهدف إلى اتباع نهج مستدام يركز على المستقبل في كل ما نقوم به.

سلامة العمال أولوية قصوى. يلتزم مصنعنا بجميع لوائح الصحة والسلامة، ويوفر تدريبًا دوريًا، ويطبق بروتوكولات صارمة في الموقع، ويزود موظفينا بمعدات سلامة متطورة. نؤمن بأن العامل الآمن هو العامل المُمَكَّن.

بالتأكيد. نفخر بقدرتنا على تقديم حلول مُصممة خصيصًا. يتعاون فريق خبرائنا بشكل وثيق مع عملائنا لفهم احتياجاتهم، مقدمين تركيبات وقصات وتشطيبات مُخصصة تُلبي متطلبات مشاريعهم.

ندير العمليات اللوجستية من خلال شركاء موثوقين، لضمان توصيل آمن وفي الوقت المناسب. يتلقى عملاؤنا معلومات التتبع فور شحن طلباتهم، ويمكنهم متابعة شحناتهم فورًا. كما أن فريق خدمة العملاء لدينا جاهز دائمًا للمساعدة.

نلتزم بجودة منتجاتنا. في حالات نادرة، في حال وجود عيوب أو عدم امتثال، نتبع سياسة إرجاع أو استبدال شفافة. نشجع عملائنا على التواصل معنا خلال فترة محددة من تاريخ الاستلام، ونعدكم بحل سريع وعادل وفقًا لشروطنا وأحكامنا.