If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp : +8613963585512

Whatsapp : +8613963585512

![]() Email : [email protected]

Email : [email protected]

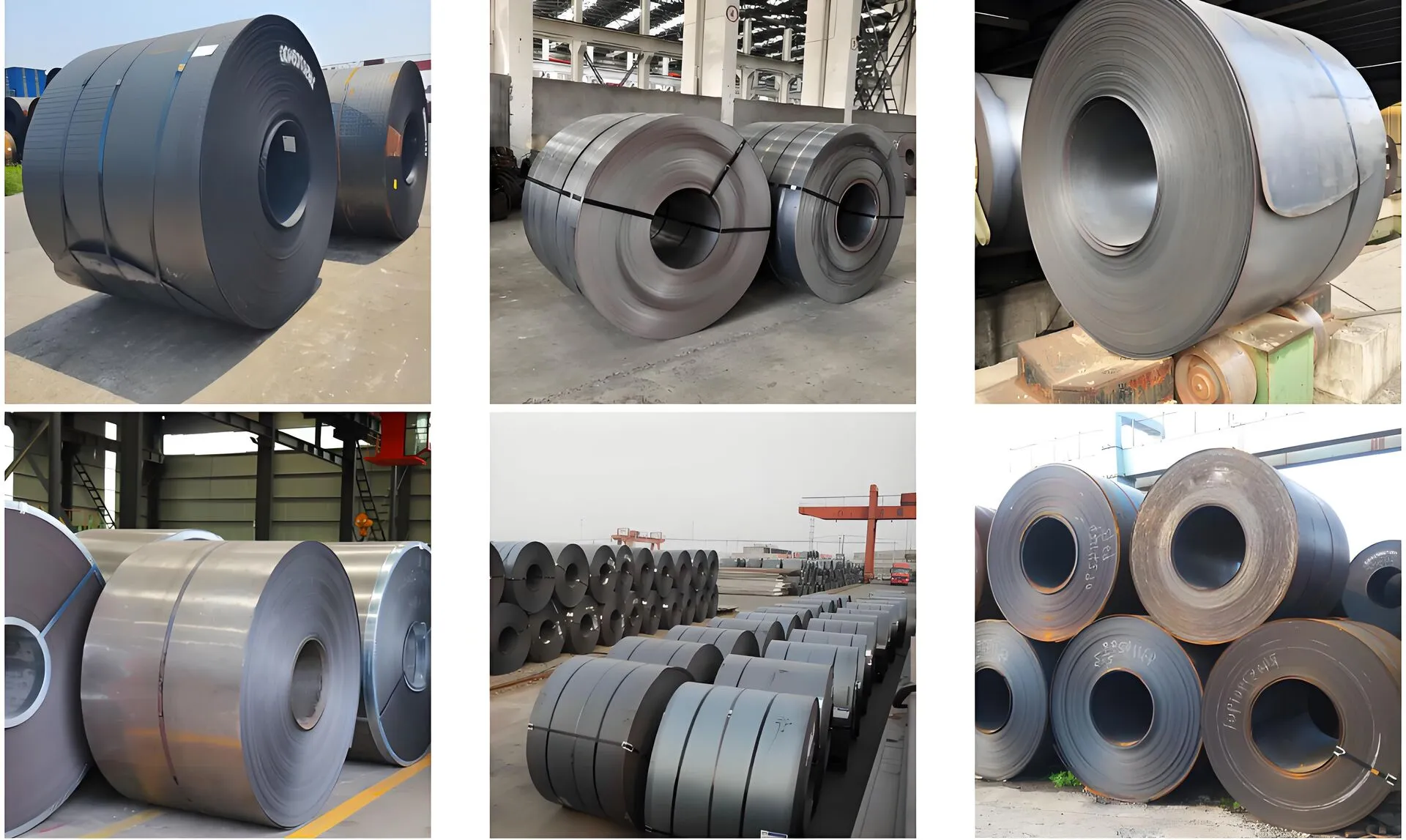

| Item | Details |

|---|---|

| Model NO. | Q195, Q235B, Q345B, SPHC, A36, st37-2 |

| Standard | ASTM, JIS, GB, AISI, DIN, BS |

| Certification | ISO, RoHS |

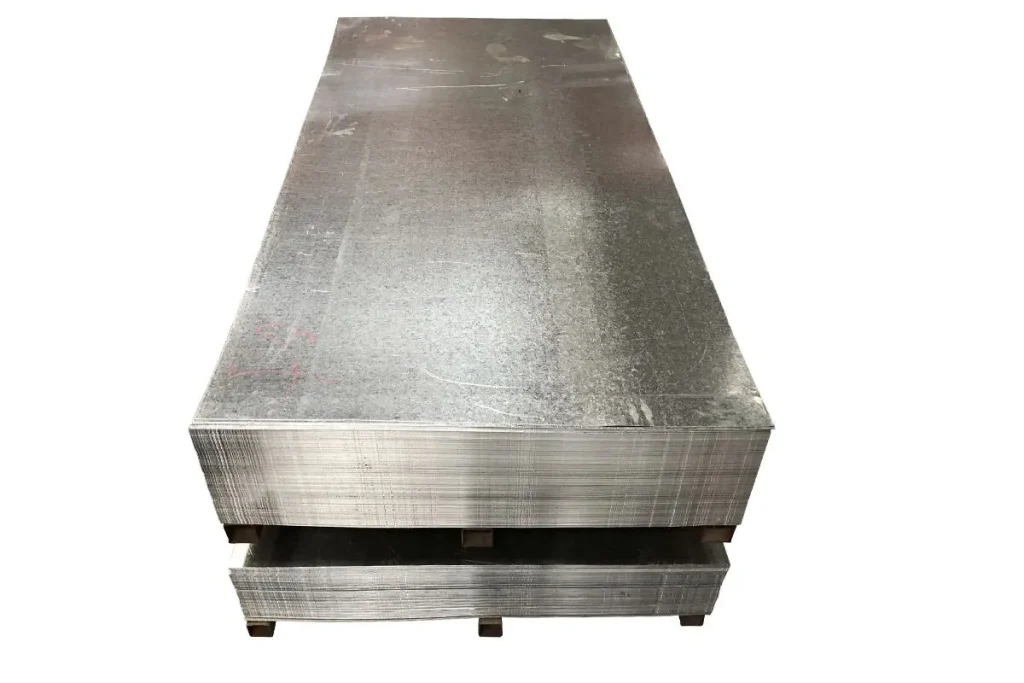

| Surface Treatment | Polished |

| Technique | Hot Rolled |

| Application | Construction, Ship Building, Machinery Manufacturing |

| Edge | Slit edge |

| Stock Status | In stock |

| Products | Carbon Steel Coil |

| Material | Q235B, A36, Q195, Ss400, St37-2, etc. |

| Thickness | 6 – 400mm |

| Width | 800 – 330mm (The most common ones are 914mm, 1215mm, 1250mm, 1000mm) |

| Surface | Black Painting, Varnish Paint, Anti Rust Oil, (the description of “Hot” is incomplete) |

| Coil Weight | 3 – 10 Mt |

| Coil Inner Size | 508mm/610mm |

| Mill Test Certificate | We can provide it. |

| Stock or Not | In stock |

| Packing | Standard Packaging |

| Transport Package | Standard Packaging |

| Specification | 3 – 10 tons |

| Origin | China |

| Production Capacity | 5000 tons per month |

Appearance:

It typically appears as a dark gray metallic color with a matte or slightly glossy surface depending on the finishing process. The surface can be treated with processes such as galvanizing, painting, or oiling to enhance corrosion resistance and aesthetic appeal.

Density:

The density of Q235B carbon steel is approximately 7.85g/cm³, which is consistent with most carbon steels. This makes it slightly denser compared to stainless steel but lighter than high-alloy steels.

Melting Point:

The melting point of Q235B carbon steel is relatively high, generally around 1480-1520℃. This enables it to maintain structural integrity in high-temperature environments, although prolonged exposure to extreme heat may affect its mechanical properties.

Coefficient of Thermal Expansion:

The coefficient of thermal expansion for Q235B carbon steel is moderate, approximately 11.7×10⁻⁶/℃ in the range of room temperature to 100℃. This characteristic ensures dimensional stability under varying temperature conditions.

Thermal Conductivity:

Q235B carbon steel exhibits good thermal conductivity, with a thermal conductivity coefficient of about 50-60W/(m·K). This is significantly higher than stainless steel, making it suitable for applications requiring efficient heat transfer.

Electrical Conductivity:

It has moderate electrical conductivity, but like most carbon steels, it is not primarily used for electrical applications. The conductivity of Q235B carbon steel is lower than that of copper or aluminum, making it unsuitable for high-conductivity requirements.

Corrosion Resistance:

Q235B carbon steel has limited corrosion resistance compared to stainless steel. It is prone to rusting when exposed to moisture or corrosive environments. However, surface treatments such as galvanizing, painting, or coating can significantly enhance its resistance to corrosion. For example, galvanized Q235B steel is widely used in outdoor applications due to its improved durability.

Oxidation Resistance:

At room temperature, Q235B carbon steel exhibits moderate oxidation resistance. However, at elevated temperatures, it is susceptible to oxidation, which can lead to scaling and reduced mechanical strength. Protective coatings or alloying elements are often used to improve its performance in high-temperature environments.

Chemical Stability:

In general chemical media, Q235B carbon steel has moderate chemical stability. It reacts with strong acids such as hydrochloric acid and sulfuric acid, leading to corrosion. However, it performs well in neutral or mildly alkaline environments, making it suitable for structural and industrial applications.

Passivation:

Unlike stainless steel, Q235B carbon steel does not naturally form a passivation layer. Surface treatments such as galvanizing or applying protective coatings are essential to prevent oxidation and corrosion. These treatments create a barrier between the steel and the environment, enhancing its lifespan.

Application:

Q235B carbon steel coils are widely used in various industries due to their excellent mechanical properties, affordability, and ease of processing. In construction, they are commonly used for structural frameworks, beams, and reinforcement bars due to their high strength and durability. In manufacturing, they are processed into components such as automotive parts, machinery frames, and pipelines. In the energy sector, they are used to fabricate storage tanks, pressure vessels, and structural supports. Additionally, in the transportation industry, Q235B carbon steel coils are indispensable for producing vehicle frames, trailers, and shipping containers. With appropriate surface treatments, they can also be used in harsh environments, such as marine structures and chemical plants.

Ultra – high strength and toughness to resist extreme loads and impacts

Ultra – high strength and toughness to resist extreme loads and impacts

With anti-corrosion treatment, it is weather-resistant and corrosion-resistant, and can serve for a long time.

100% recyclable, reusable, low-carbon and consumption-reducing

The processing is rapid and precise, and the project is delivered quickly.

Pass international certifications such as ISO and ASTM, with reliable quality.

Create exclusive specifications and shapes as needed

Global service team, providing full – course after – sales technical support

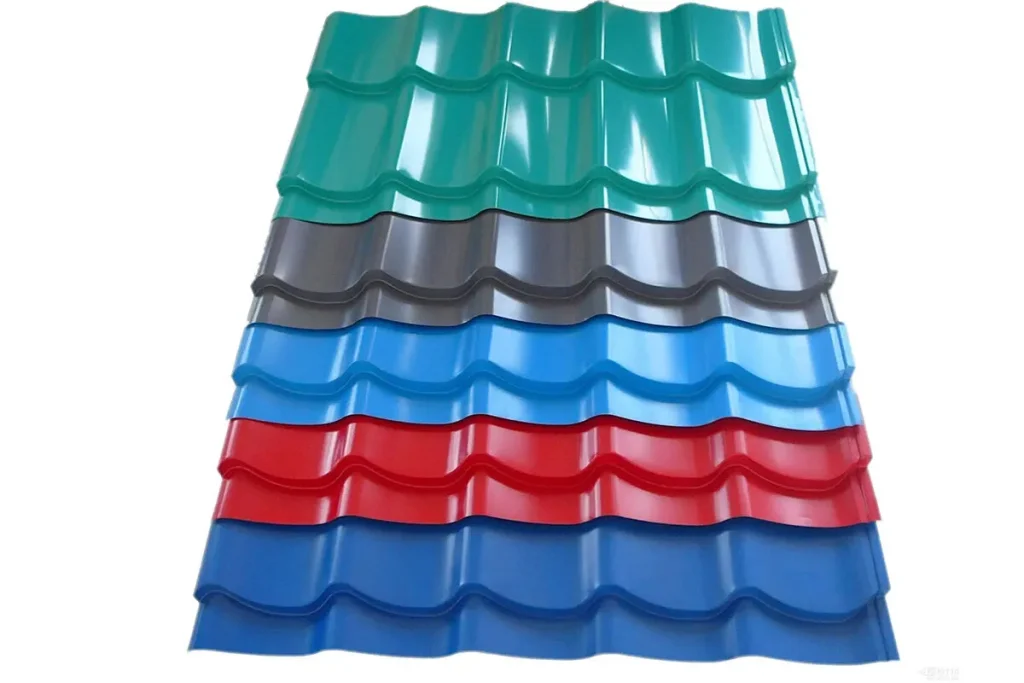

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.