If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

![]() Whatsapp : +8613963585512

Whatsapp : +8613963585512

![]() Email : [email protected]

Email : [email protected]

| Item | Details |

|---|---|

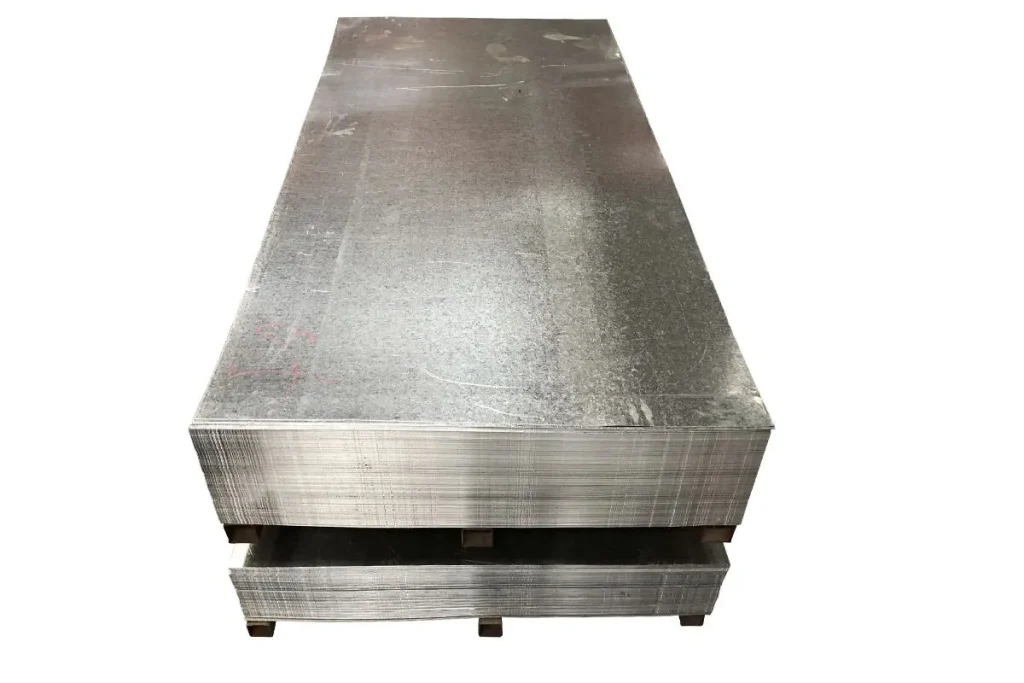

| Product Name | 316L Stainless Steel Sheet |

| Length | As required |

| Width | 3mm – 2500mm or as required |

| Thickness | 0.3mm – 300mm or as required |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Technique | Hot rolled |

| Surface | NO.1 or according to customer’s requirement |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321, 310S, 309S, 410, 410S, 420, 430, 431, 440A, 904L |

| Application | It is widely used in high-temperature applications, medical devices, building materials, chemistry, the food industry, agriculture, and ship components. It also applies to food and beverage packaging, kitchenware, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screens. |

| MOQ | 1 ton. Sample orders are acceptable. |

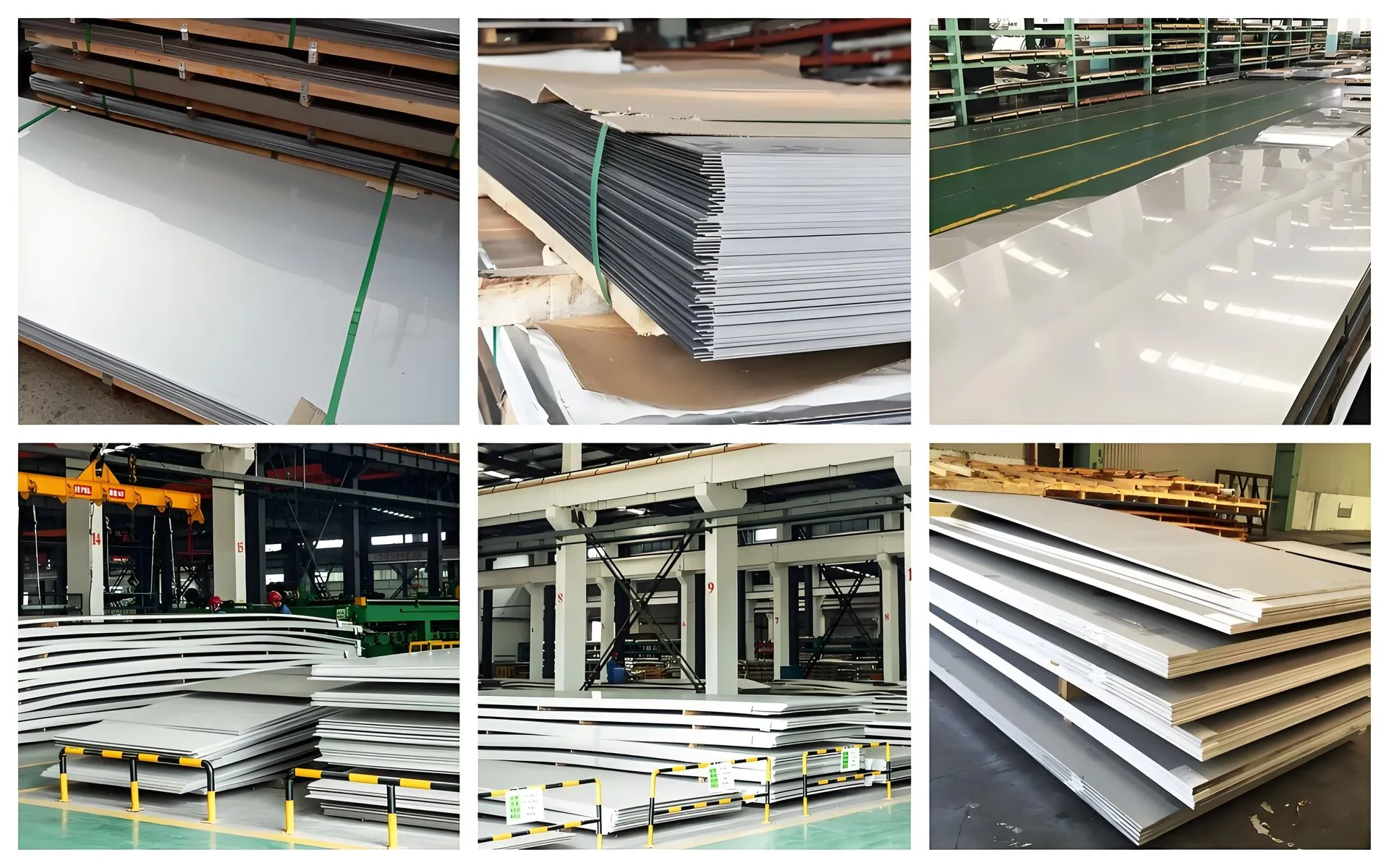

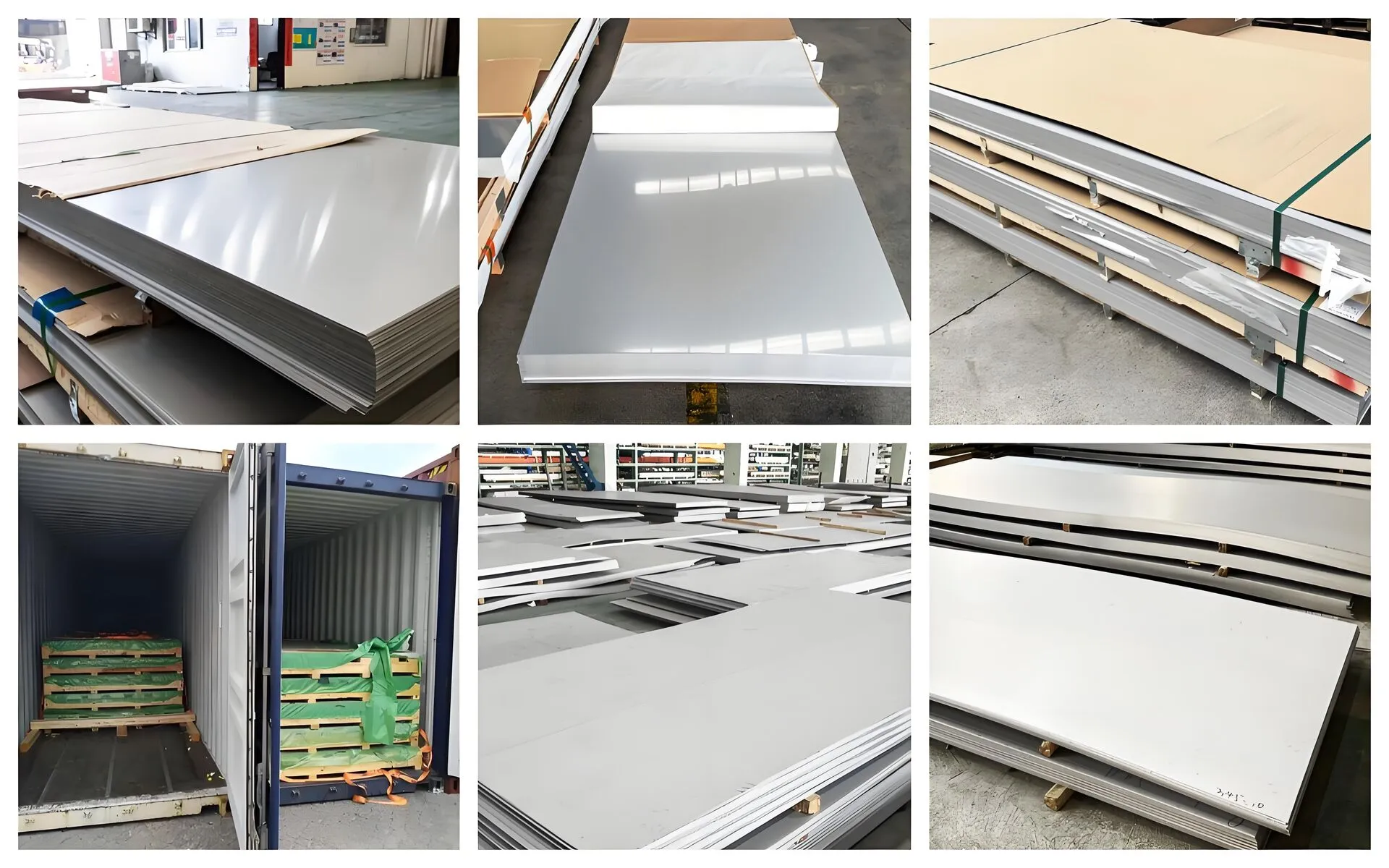

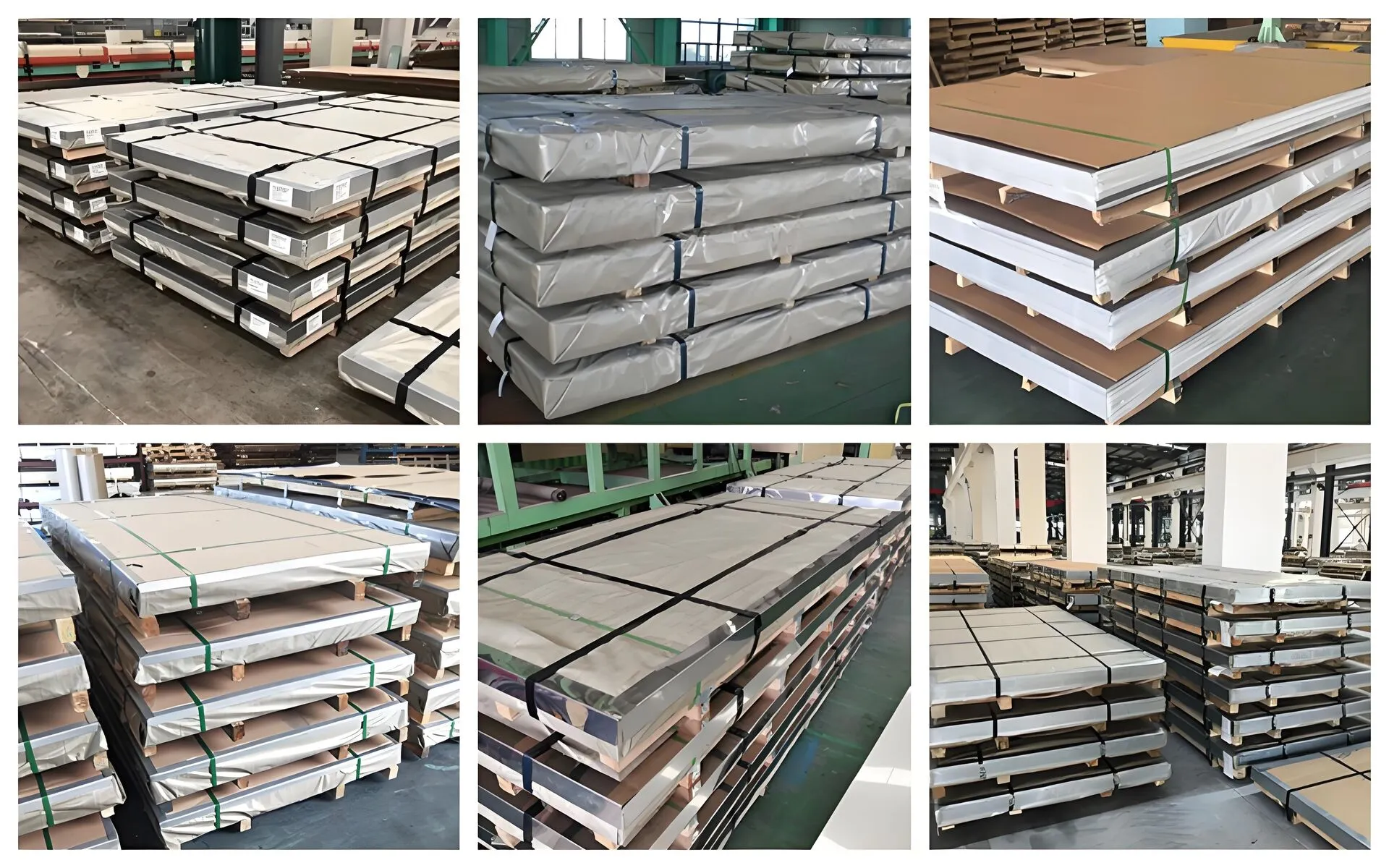

| Export Packing | Packed with waterproof paper and steel strips. Standard export seaworthy package. Suitable for all kinds of transportation, or as required. |

| Packing | Standard export packing for stainless steel sheets: 1. Surface polish 2. Bundle package 3. Wooden case, wooden pallet package 4. Container or bulk 5. Special packing according to customer’s request |

Appearance:

It usually presents a silvery white metallic color, with a smooth surface and high gloss. Different surface effects can be obtained through different surface treatment processes, such as mirror polishing, brushing, etc. 316L stainless steel plates are widely used in applications where aesthetic appeal and corrosion resistance are highly valued.

Density:

The density is generally about 7.98g/cm³. For example, the density of 316L stainless steel plate is slightly higher than that of ordinary carbon steel, making it suitable for demanding structural applications.

Melting point:

The melting point is relatively high, generally around 1398-1454℃. For example, the melting point of 316L stainless steel is about 1400-1450℃, which makes it exhibit good stability in high-temperature environments.

Coefficient of thermal expansion:

The coefficient of thermal expansion is relatively small. In the range of room temperature to 100℃, the coefficient of thermal expansion of 316L stainless steel is about 17.2×10⁻⁶/℃. This feature enables it to maintain good dimensional stability in environments with significant temperature changes.

Thermal conductivity:

The thermal conductivity is poor, and its thermal conductivity coefficient is about 16 – 27W/(m・K), which is much lower than that of copper, aluminum, and other metals, so it has certain thermal insulation performance.

Electrical conductivity:

It has certain electrical conductivity, but the conductivity is relatively low. The conductivity of 316L stainless steel is about 1.4×10⁶ S/m, which is only about 4% of the conductivity of copper.

Corrosion resistance:

This is one of the most important chemical properties of 316L stainless steel plates. Because a dense passivation film can be formed on its surface, this passivation film prevents oxygen, water, etc., from contacting the metal matrix, thereby effectively preventing corrosion. For example, 316L stainless steel has excellent corrosion resistance in environments such as atmosphere, water, weak acids, and alkalis; it also contains molybdenum, making it highly resistant to chloride ion corrosion. It is often used in marine environments or chemical environments exposed to chloride ions.

Antioxidation:

316L stainless steel plates have good oxidation resistance at both room temperature and higher temperatures. For example, they can withstand high temperatures in demanding environments without being easily oxidized and are suitable for use in high-temperature furnace components and other applications.

Chemical stability:

In general chemical media, 316L stainless steel plates exhibit high chemical stability and are not prone to chemical reactions with common chemicals. However, in some specific strong corrosive media, such as concentrated nitric acid, hydrofluoric acid, etc., the corrosion resistance of 316L stainless steel may be affected.

Passivation:

After the 316L stainless steel plate is exposed to air or undergoes passivation treatment, a passivation film forms on the surface. This passivation film enhances the material’s corrosion resistance and oxidation resistance. Passivation treatment typically involves immersing the stainless steel plate in a solution containing an oxidant, such as nitric acid or potassium dichromate, to promote the formation and repair of the passivation film.

316L stainless steel plates are widely used in many fields due to their excellent corrosion resistance, high strength, and good processing performance. In the medical field, they are used to manufacture surgical instruments, implants, etc., ensuring sterility and biocompatibility. In the building and decoration industry, they are often used to create railings, handrails, and artistic sculptures, combining beauty with durability. In mechanical manufacturing, they are processed into key components such as structural parts and gears to ensure stable operation of equipment. In the food processing industry, they are used to manufacture food machinery and containers to meet strict hygiene standards. Additionally, in fields such as chemical equipment, electronic appliances, etc., 316L stainless steel plates are indispensable. They are used to manufacture reactors, valves, electronic equipment housings, etc., and can adapt well to complex working environments.

Ultra – high strength and toughness to resist extreme loads and impacts

Ultra – high strength and toughness to resist extreme loads and impacts

With anti-corrosion treatment, it is weather-resistant and corrosion-resistant, and can serve for a long time.

100% recyclable, reusable, low-carbon and consumption-reducing

The processing is rapid and precise, and the project is delivered quickly.

Pass international certifications such as ISO and ASTM, with reliable quality.

Create exclusive specifications and shapes as needed

Global service team, providing full – course after – sales technical support

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.